Steve Sanford

Well-known member

All~

My "bench" has been overflowing with a bewildering array of gunning stool - Herter's, Chesapeakes, E Allens, Wildfowlers - needing to be put back into working trim. There is somewhere between 40 and 50 birds - of 6 or 7 species..... And, I just custom-cut some parts for a friend's IKEA kitchen cabinets, fed some neighbor's goats with the many limbs that came down in our recent heavy snow, and cut a horse-trail onto our farm for another neighbor....

These Herter's Model 81 Brant heads were removed - one requiring a creative new approach - from the over-size Model 92 bodies. They were then coated (epoxy + fine sawdust) and primed and will go back onto Model 81 bodies once they have received their topcoats. To my eye, the life-size head on the over-size body never looked right - an abrupt and "un-fair" transition from neck to breast. And, the Model 81 Brant is already over-size - and makes a fine gunning decoy once the foam bodies are hardened.

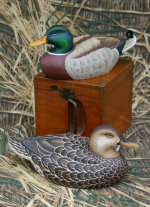

Not many photos of the rest of the fleet yet. So, I give you some nascent Green-wings From the Bench of George Williams:

All the best,

SJS

My "bench" has been overflowing with a bewildering array of gunning stool - Herter's, Chesapeakes, E Allens, Wildfowlers - needing to be put back into working trim. There is somewhere between 40 and 50 birds - of 6 or 7 species..... And, I just custom-cut some parts for a friend's IKEA kitchen cabinets, fed some neighbor's goats with the many limbs that came down in our recent heavy snow, and cut a horse-trail onto our farm for another neighbor....

These Herter's Model 81 Brant heads were removed - one requiring a creative new approach - from the over-size Model 92 bodies. They were then coated (epoxy + fine sawdust) and primed and will go back onto Model 81 bodies once they have received their topcoats. To my eye, the life-size head on the over-size body never looked right - an abrupt and "un-fair" transition from neck to breast. And, the Model 81 Brant is already over-size - and makes a fine gunning decoy once the foam bodies are hardened.

Not many photos of the rest of the fleet yet. So, I give you some nascent Green-wings From the Bench of George Williams:

All the best,

SJS

Last edited: