What is used in them for the foam, are the original ingredients still available?

I use a lot of their molds. Most of my uprights come from decoy unlimited molds. I have an unfinished diver body mold that was half machined for the screw on top. I plan on threading and finding the 1.5" thread cap to put in it and start making divers next year. I will definitely keep using them, but starting to move onto other mold making and custom stuff. I have some carves coming that I will make molds out of and cast foam that way.

In these instructions they are talking about EPS beads. You can still buy them, it is the foam that you see with white foam cups. You put them in the mold, boil them for so much time, and they expand and fuse together. Out comes a decoy mold. I use 2 part urethane with Cammie 980 release agent. This release agent takes rustoleum paint really well and I do not have to put any sanding on the foam to get paint to stick. I like 2 part urethane because it is quick. I can cast a foam body in about 5 minutes. With EPS beads you have to have a big tub to boil water, use a heating source (usually a propane burner), run that until water is boiling and then I believe it takes 5-10 min (do not quote me on this, as I have only watched videos and cannot remember what those videos stated but I have never actually played with EPS beads) in boiling water for beads to expand. Takes too much time and there is additional cost in propane and time lost in waiting for water to boil.

The pros to eps beads, no need for release agent. Cons - time and extra costs to make a mold

The pros to urethane foam, quick easy casting, also different variations of foam strengths (2 lb, 4 lb, 8 lb, etc etc). The heavier the foam, the more durable but less expansion. Cons - release agents can make it difficult to paint. Cammie 980 is a winner for how I paint though, and I can pull from the mold and instantly start applying rusto paint if I wanted to and it would take without issue. Some people have stated they have to wash their foam molds with dawn soap and water and let dry for a day to paint.

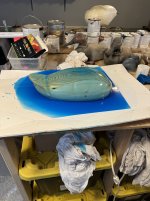

Dave Diefenderfer has helped open my eyes to making molds with fiberglass cloth and epoxy. Just got some in the mail yesterday and plan on trying his technique on the next mold I make. I had a carver make me a generic body so I could practice making a mold. I used silicone and hardened plaster, but Dave uses fiberglass and it looks much cleaner. I plan on adopting his technique for this process.

Here are some pics of uprights that came from a decoys unlimited mold and some skimmers that I made from a custom mold I made. Look at the plaster and how ugly it looks. I dont like that and plan on using fiberglass instead to hold the silicone mold. Hope this helps.