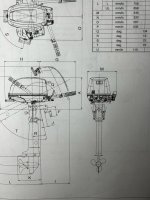

I'm hoping to add a mount to the transom of my duckboat. The 2 photos below illustrate how it sits on the boat now, and how it would sit on the transom if I fabricate a mount along the lines of the model shown.

For years, with 3 separate motors, a problem arises from time to time where the propeller will spin at high rpms without propelling the boat. I'm pretty sure the present setup (where the motor sits on a 90-degree transom is making the propeller suck in air, and resulting in this problem.

When I constructed this boat, I didn't know much. In retrospect I think I should have angled the transom.

I suspect that putting an angled motor mount on the transom will solve the problem. The model mount is angled 11 or 12 degrees, and with that angle the 3rd pin gets the anti-ventilation plate the closest to horizontal. I estimate this moves the propeller about 4 inches further rearward from the back of the transom.

I'd greatly appreciate any insights the braintrust on duckboats can share. So far, I have the following thoughts (thanks for anything you can share):

For years, with 3 separate motors, a problem arises from time to time where the propeller will spin at high rpms without propelling the boat. I'm pretty sure the present setup (where the motor sits on a 90-degree transom is making the propeller suck in air, and resulting in this problem.

When I constructed this boat, I didn't know much. In retrospect I think I should have angled the transom.

I suspect that putting an angled motor mount on the transom will solve the problem. The model mount is angled 11 or 12 degrees, and with that angle the 3rd pin gets the anti-ventilation plate the closest to horizontal. I estimate this moves the propeller about 4 inches further rearward from the back of the transom.

I'd greatly appreciate any insights the braintrust on duckboats can share. So far, I have the following thoughts (thanks for anything you can share):

- How far rearward of the transom does the propeller need to be to avoid sucking in air

- How far rearward is too far

- Is 11-12 degrees a good angle for the motor mount

- What material is best for making this (I've read quite a few of Steve Sanford's posts on this. Clearly, he likes to use treated southern yellow pine. I believe his has dried for a long time, however, and I don't have any dried material. I agree with Steve's observation that epoxy doesn't stay well on white oak. I've had the same experience. My boat, being quite small, fits well in my garage, so it's only been exposed to the weather when I use it, so will I be fine not using pressure treated. If so, is the drying a must, and if so, for how long, and how).

- How to attach the wedges to the existing transom (It looks like Steve Sanford's Southbay Duckboat Motor Mounts run parallel to the transom so that his bolts that run through the transom and mount sit perpendicular at both ends, but I'll only be able to have one end perpendicular)