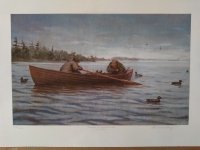

I heading out in search of some marine plywood today. I stopped into a local boat builder, they build "chaloupe Vercheres". They build traditional small wooden that were used for hunting on the St. Lawrence. There is a nice little write up on them here: .

https://www.duckworksmagazine.com/01/articles/chaloupe/index.htm#google_vignette. He was nice, but could not provide a lot of help, but he gave me the contact of another builder. I dropped by and he was a wealth of information. He's retired from boat building and did he's training in Maine in the 1970s. He specialized in restoring vintage Chris-Craft boats. He provided his connections on local supply of lumber and his sources of plywood. Real nice guy, we talked to 2 1/2 hours and welcomed me back any time.

Got back to the boat this afternoon and I kept looking at the blocking between the inner keel and the buttons at the frame in front of the cockpit. The just make no sense to me -- can't understand their purpose. I decided to try and route one out -- I sanded of the top and could not see any nail heads -- I did not get very far before I hit one. That little block of wood maybe 6"x6" had 13 ss ring nails in it. It looks like a porcupine!

Here's what it looked like before

View attachment 59166

And after

View attachment 59167Saturated with water. It was bedded in some sort of rubber compound and the hull of the boat is wet there too and have to go. The builder I me today said he could build me a new one way faster then repairing this one.

Scott