Scott Gilliland

Member

With no help to turn the boat over I picked at a few things that were bothering me.

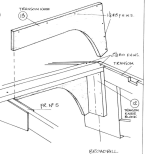

1: Rub Rails - there are a couple of sections of the rub rails where there are gaps between the rail and the hull. Using a heat gun and putty knife, I was able to release a section of the rail. I thought the rail was separating from the hull, but it was a bad fairing job. With a bit of sanding it fits tight to the hull now. I'll epoxy it in place later.

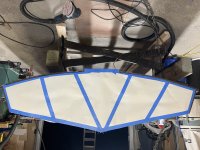

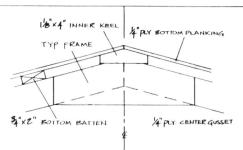

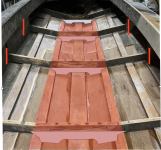

2: I took to sanding the inside of the hull. I've bared large sections and the water damage appears to be restricted just to the areas I'd discovered previously. nothing new . Those blocks between the battens in the front of the boat were located at butt joints between the sheets of plywood. I did find the in the plans. They were nailed and bedding in that black rubber like compound. I failed to keep the water out and I removed them.

. Those blocks between the battens in the front of the boat were located at butt joints between the sheets of plywood. I did find the in the plans. They were nailed and bedding in that black rubber like compound. I failed to keep the water out and I removed them.

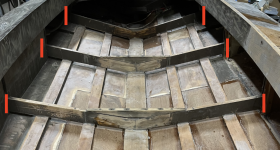

3: The frame are made off 5 pieces. Three pieces that form the frame and 2 plywood gussets. The looked like places that could hols water so I removed them. Small areas of one Rame has a little water damage and all were damp under that black rubber company. With the plywood and rubber removed, and sanded they look in good shape.

I'm not sure what kind of wood was used. The battens and rub rails have a pinkish/red tinge; I'm guessing mahogany. The frames, rub rails, and I think the inner keel are all oak. They seem to be in great shape despite being a bit damp and I'm guessing white oak.

Lots more sanding to go.

1: Rub Rails - there are a couple of sections of the rub rails where there are gaps between the rail and the hull. Using a heat gun and putty knife, I was able to release a section of the rail. I thought the rail was separating from the hull, but it was a bad fairing job. With a bit of sanding it fits tight to the hull now. I'll epoxy it in place later.

2: I took to sanding the inside of the hull. I've bared large sections and the water damage appears to be restricted just to the areas I'd discovered previously. nothing new

3: The frame are made off 5 pieces. Three pieces that form the frame and 2 plywood gussets. The looked like places that could hols water so I removed them. Small areas of one Rame has a little water damage and all were damp under that black rubber company. With the plywood and rubber removed, and sanded they look in good shape.

I'm not sure what kind of wood was used. The battens and rub rails have a pinkish/red tinge; I'm guessing mahogany. The frames, rub rails, and I think the inner keel are all oak. They seem to be in great shape despite being a bit damp and I'm guessing white oak.

Lots more sanding to go.