Scott Gilliland

Active member

Well, I thought about it a lot. Had a friend come over and look at it and we agreed that the boat would be much mode practical without those frames.... I just cut them out. It looks much better and it is a lot easier to work on.

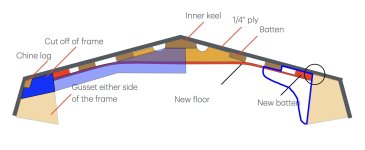

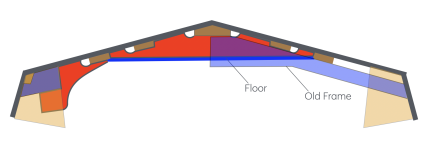

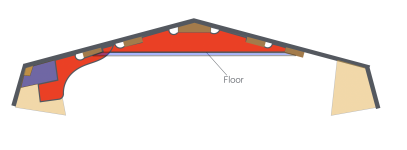

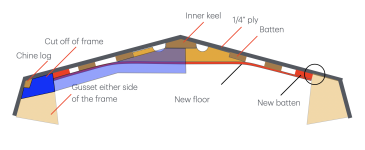

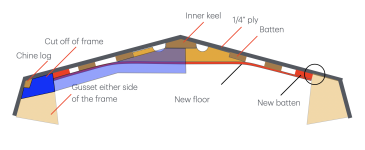

After thinking about it this is what I decided on. I cut out the light blue portion of the frame. I will add a third batten either side of the hull just inside of where the old frame was cut off. I will add small frame that will span over the keel between the 2 inner battens (orange). The keel, batten and chine logs will get a fillet of epoxy on either side. The chine logs and keel will be taped with glass. I will create a sandwich with an inner floor of 1/4" plywood covered with glass. This idea came from Eric. I think it will be very strong. The only weak spot maybe where the new batten butts against the old frame. I could not figure out how to join them (area in the circle in the diagram). I removed 4 frames and they with be replaced with 8 of the smaller frames/braces along the length of the keel.

I think it will make a very clean strong hull. Little hard to clean the mud that will collect under new floor. I'm committed now!

After thinking about it this is what I decided on. I cut out the light blue portion of the frame. I will add a third batten either side of the hull just inside of where the old frame was cut off. I will add small frame that will span over the keel between the 2 inner battens (orange). The keel, batten and chine logs will get a fillet of epoxy on either side. The chine logs and keel will be taped with glass. I will create a sandwich with an inner floor of 1/4" plywood covered with glass. This idea came from Eric. I think it will be very strong. The only weak spot maybe where the new batten butts against the old frame. I could not figure out how to join them (area in the circle in the diagram). I removed 4 frames and they with be replaced with 8 of the smaller frames/braces along the length of the keel.

I think it will make a very clean strong hull. Little hard to clean the mud that will collect under new floor. I'm committed now!

Last edited: