You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Greenhawk neck weight mold

- Thread starter Dtown

- Start date

Lawrence Kotchek

Active member

I have one of these I would be willing to sell. Need to dig it out

William Reinicke

Active member

Interesting! I have never ever cast lead and never plan on it. Funny story though, when I was growing up many people on the block were bass fisherman, including my pops. The family 5 houses down made their own jig heads. They were BEYOND generous and gave everyone some jig heads growing up. We thought they were awesome neighbors. It came out years later, the parents were sending the kids out on their bikes and stealing the lead counter weights off tires to make jig heads. I died laughing when I finally found out, but many on the block were very upset. I thought it was kind of ingenious but naturally a tire is much mor expensive than lead.This is 2 dozen for $73 with free shipping! That is a very good deal. Less than $3 each. If you can do it cheaper, I would be surprised. I am always scrounging lead and have a stockpile, but it takes hours to mold and propane to burn to make that many weights. There is a sweet spot on the lead temp and the mold temp. Go to fast and you have weak anchors, go too slow and they don't pour smooth, and you need to recast it.

I do make my own soft plastics for bass fishing. I have some pretty neat colors that really do well in our local bodies of water. For the most part just black, blue, green pumpkin, roadkill, junebug, morning dawn, red bug and watermelon red are what I pour but we have a body of water where the crawfish have lots of blue changing effects and we have red clay in another lake that turns the fry a pink color. So made some custom stuff for those bodies of water and have done very well with subtle little color differences that cannot be necessarily bought off a shelf. I would think casting lead is very similar to plastisol. Too hot and its runny and doesnt set up well, and not hard enough and its not filling the form.

Scott Farris

Well-known member

Hi, I have the mold and haven't used it in over 20 years. It has never been my favorite as the trade off between better holding ability in current is offset by the reduced flexibility of wrapping the line and tieing it off easily that a classic "H-section" anchor provides.

Casting lead is fun as long as you understand it's wicked hot and if you get water into a pot with molten lead it will explode. A buddy has scars on his hands and wrists from trying to use a plaster of Paris mold that wasn't fully cured. I can't imagine what a full pot would do. Do your casting out side over a chunk of something that won't catch fire and that you can clean up.. After a casting party back in the early 2000s I have lead melted into my driveway in multiple areas but we did have a blast.

from 2002 and old names

BJ & me

Paul D

If you feel you need the mold PM me and maybe we can make a deal.

Casting lead is fun as long as you understand it's wicked hot and if you get water into a pot with molten lead it will explode. A buddy has scars on his hands and wrists from trying to use a plaster of Paris mold that wasn't fully cured. I can't imagine what a full pot would do. Do your casting out side over a chunk of something that won't catch fire and that you can clean up.. After a casting party back in the early 2000s I have lead melted into my driveway in multiple areas but we did have a blast.

from 2002 and old names

BJ & me

Paul D

If you feel you need the mold PM me and maybe we can make a deal.

Vince Pagliaroli

Well-known member

You should NEVER place molten metal on water.

I've witnessed some incredible explosions straight from hell while working in the Steel Mill when molten steel met water. The explosions and the aftermath are things that one does not easily forget. I have many decoy anchors of all types and sizes and never made a damn one of em cuz of that.

I've witnessed some incredible explosions straight from hell while working in the Steel Mill when molten steel met water. The explosions and the aftermath are things that one does not easily forget. I have many decoy anchors of all types and sizes and never made a damn one of em cuz of that.

Scott Farris

Well-known member

Vince, are you one of those guys who want to live forever? As a waterfowler I'd of thought you'd be comfortable with controlled risks. Not much "safe" about late season hunting, you simply control what you can, keep your gear in good shape and trust your buddies. Lead casting can be a disaster but you have to screw up. In forty years of casting and hanging out with others that made me look like an amateur I've never (knock on wood) had a problem. That's many thousands of bullets and round balls, hundreds of jig heads, fluke balls, hundreds of decoy wts. and dozens of 5lb dive wts. Not to mention things like scull boat bow wts. I was always jealous of the kid across the street who had a set up to cast his own lead soldiers. I'm sure it was originally his dad's but he was using it. The sixties were a great time to be a kid!

Very best!

Scott

Very best!

Scott

Vince Pagliaroli

Well-known member

Scott,

I do not wanna live forever just enjoy the things I do and did as long as I can. Doing things for a living and playing around with them are different things. Ya do enough at work ya don't wanna do it at home. Lots of my buddies cast lead for all the things you wrote. I traded my art and carvings for them. Have enough jig heads to fill a store... Lead I use for decoys I have aplenty. As my buddy sez "If yer gonna be tough ya gotta be stupid." I'm somewhere in between. I was a kid in the 1950's lead paint sure was tasty. HHHEEEEeeeeeHHHHHHEeeeeeeHHHHEEEeeeee Ain't no such thing as "safe" especially on guns.

95% of my fishing now is dry & popper fly fishing and have no use for lead even though I still have lots of it.

Best regards

Vince

I do not wanna live forever just enjoy the things I do and did as long as I can. Doing things for a living and playing around with them are different things. Ya do enough at work ya don't wanna do it at home. Lots of my buddies cast lead for all the things you wrote. I traded my art and carvings for them. Have enough jig heads to fill a store... Lead I use for decoys I have aplenty. As my buddy sez "If yer gonna be tough ya gotta be stupid." I'm somewhere in between. I was a kid in the 1950's lead paint sure was tasty. HHHEEEEeeeeeHHHHHHEeeeeeeHHHHEEEeeeee Ain't no such thing as "safe" especially on guns.

95% of my fishing now is dry & popper fly fishing and have no use for lead even though I still have lots of it.

Best regards

Vince

Lawrence Kotchek

Active member

Reclaiming lead can be laborious, but getting a system and sequence down is relatively easy. Most of my "mixed lead" goes into decoy weights and some fishing sinkers. Most of my "pure lead" goes into jigs and other fishing lures. Some of the bullets I cast, are mixed led and some are pure lead, depending on if the bullet will be used for target shooting or used for hunting.There is a sweet spot on the lead temp and the mold temp. Go to fast and you have weak anchors, go too slow and they don't pour smooth, and you need to recast it.

Some of the older weights were getting beat up so I made some new ones.

I drew up a print, then remembered I already had a mold. Yes, a CNC machined aluminum mold can be made, but a mold cut as shown in my drawing, can be done on a manual machine as well.

Want more weight or a larger ring, just adjust dimensions. If you have the desired shape and size just duplicate it. Many back yard molds have been machined into a hardwood block, using a hand held wood router and template. Very easy and cheap to do.

I use an electric heated bottom pour pot, to cast everything except the decoy anchors. The decoy anchors require more "pour volume" than the nozzle on my electric pot will provide. The nice advantage to the electric melting pot is the precisely controlled heat.

William Reinicke

Active member

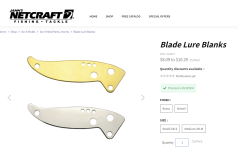

How much you sell your blade baits for??? I need me some of them for fall white bass. They MUNCH blade baits here.Reclaiming lead can be laborious, but getting a system and sequence down is relatively easy. Most of my "mixed lead" goes into decoy weights and some fishing sinkers. Most of my "pure lead" goes into jigs and other fishing lures. Some of the bullets I cast, are mixed led and some are pure lead, depending on if the bullet will be used for target shooting or used for hunting.

View attachment 60251

Some of the older weights were getting beat up so I made some new ones.

View attachment 60250

I drew up a print, then remembered I already had a mold. Yes, a CNC machined aluminum mold can be made, but a mold cut as shown in my drawing, can be done on a manual machine as well.

Want more weight or a larger ring, just adjust dimensions. If you have the desired shape and size just duplicate it. Many back yard molds have been machined into a hardwood block, using a hand held wood router and template. Very easy and cheap to do.

View attachment 60252

I use an electric heated bottom pour pot, to cast everything except the decoy anchors. The decoy anchors require more "pour volume" than the nozzle on my electric pot will provide. The nice advantage to the electric melting pot is the precisely controlled heat.View attachment 60253

I make them for my own use.How much you sell your blade baits for??? I need me some of them for fall white bass. They MUNCH blade baits here.

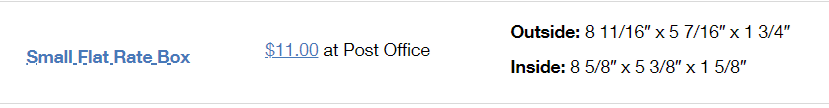

Just as an example; you want 25 brass in size ZB-S and 25 nickel in size ZB-M, you need to send me those blanks, PLUS 50 nickel in size ZB-S for me to keep for myself..

Or another example; you want 12 nickel in size ZB-S, you need to send me the entire 25 pack of ZB-S, I will add the lead in either 1/4 and/or3/8 ounce weight and send 12 back to you for the actual cost of shipping.

You would need to paint as desired, add hooks and line snap to complete your lures.

ZB-S is good for 1/4 and 3/8 ounce lures. ZB-M is good for 1/2. 5/8 and 3/4 ounce lures.

Blade Lure Blanks

DetailsUsed to form the body in our vibrating blade and shad blade molds. Blade sizes are not interchangeable.

Please note, I have not done the math to see if this even makes economical sense for you,,,,,,,,,,,,,, or me. HA!

justin boucher

New member

How much would you sell the anchors for if i were to drive up to you?Had the mold decades ago - lent and never returned, I believe. I do have dozens of the anchors - but would hardly pay to ship to the Central Flyway. (I may bring them to the SSWA Duckboat Show on Long Island this weekend.)

I switched from ring anchors to mushrooms for most of my rig long ago. One reason was that the lip on these dug into the breasts of our Herter's Model 72 Durlon foam.

Best of luck!

SJS

William Reinicke

Active member

Thats pretty damn good price for a CAD and a CNC run. When I looked into doing this for custom baits for bass fishing, the lowest quote I could find was ~$350. That was years ago though.I have looked at a few different sites that will use a CNC cutter to make you a mold. I wanted to get a custom decoy anchore done and one shop I believe quoted me $150 for it. They do the CAD drawing and use the CNC to cut it out. Probably a good way to go.