Cameron ziesak

New member

First time poster long time lurker. I bought an older home built glass scull that my dad found in a customers car port with 30+ years of dust on it back in 2020. After getting it to the house what I thought would be a wash and go restore turned into my first experience doing glass work when some cracks and delamination showed themselves when I started sanding for a new paint job.

After a few years of mostly ignoring the project I got all the cracks fixed and a new battleship grey paint job on it. Only problem was the oars that the boat had were filled with powder post beetle holes and had chipped blades. So I made an oar using a shovel handle and marine grade plywood for the blade. It worked great until it didn’t. I got into a good rhythm and smacked some tules cracking the blade it the shaft. I should have used some glass at the junction but didn’t. So I redid my oar with glass and for the tiny amount of time I got to scull it worked….. until the boot showed how dry rotted it really was and fell apart mid scull leading to me being the little Dutch boy with my hand in the hole as dad set a rowing speed record back to the truck. At that point college finals, work, and crappy weather were all I got for the rest of season.

(Note old slightly chipped oar in sculling hole. It works but wants to go in circles)

(Note old slightly chipped oar in sculling hole. It works but wants to go in circles)

That leads to this season. I’m making a couple new oars with Doug fir blades, adding a new leather around the hole, building a lid so I can keep the scull at my house, and making a new boot.

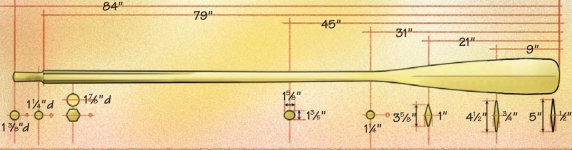

Today I made a jig out of some scrap plywood to make consistent angles to attach the Douglas fir 1 9/16” railing handle to the blade as I plan to make a lot of versions to try. I am by no means even a novice at wood working or sculling so this is all trial by breaking stuff.

After a few years of mostly ignoring the project I got all the cracks fixed and a new battleship grey paint job on it. Only problem was the oars that the boat had were filled with powder post beetle holes and had chipped blades. So I made an oar using a shovel handle and marine grade plywood for the blade. It worked great until it didn’t. I got into a good rhythm and smacked some tules cracking the blade it the shaft. I should have used some glass at the junction but didn’t. So I redid my oar with glass and for the tiny amount of time I got to scull it worked….. until the boot showed how dry rotted it really was and fell apart mid scull leading to me being the little Dutch boy with my hand in the hole as dad set a rowing speed record back to the truck. At that point college finals, work, and crappy weather were all I got for the rest of season.

(Note old slightly chipped oar in sculling hole. It works but wants to go in circles)

(Note old slightly chipped oar in sculling hole. It works but wants to go in circles)That leads to this season. I’m making a couple new oars with Doug fir blades, adding a new leather around the hole, building a lid so I can keep the scull at my house, and making a new boot.

Today I made a jig out of some scrap plywood to make consistent angles to attach the Douglas fir 1 9/16” railing handle to the blade as I plan to make a lot of versions to try. I am by no means even a novice at wood working or sculling so this is all trial by breaking stuff.