Steve Sanford

Well-known member

While gunning from Craig Kessler's 17-foot TDB last weekend, I could not help but notice that all but one of the original "shell racks" was broken. So, amongst the Christmas carvings and other projects - as wll as some spotty gunning hereabouts - I made these racks today - for Craig's boat. In some earlier boats, I had bored shell holders right into the "lip" on my shelves. I used 5/4 stock for the lip at the time. These are made to fasten (deck screws will be fine) right to the existing shelf.

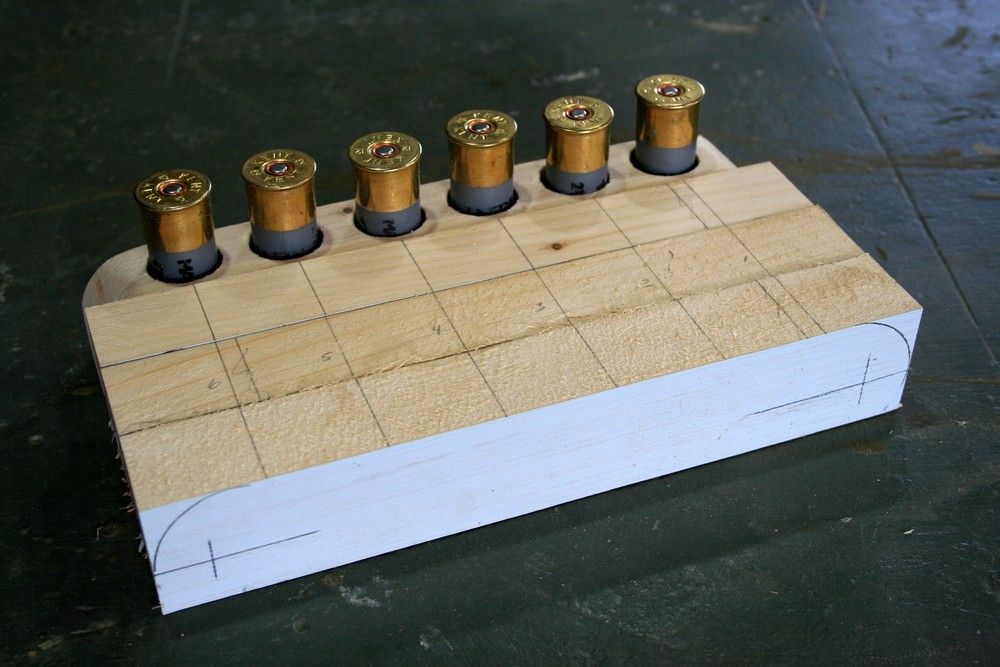

Here's a sketch. I used 5/4 White Pine. No magic here - just easy to do when I'm in my own shop - and no out-of-pocket expense.

I made 4 and mass-produced as much as I could. Unlike the factory racks, these allow the bullets to stick up where I can grab them more easily.

I used a 7/8" Forstner bit - but a spade bit would work. I tried 13/16" but it was a bit snug - likely to bind if the wood swelled just a bit. These are for 12 gauge, of course.

I set the fence on my drill press so I stayed on the centerline.

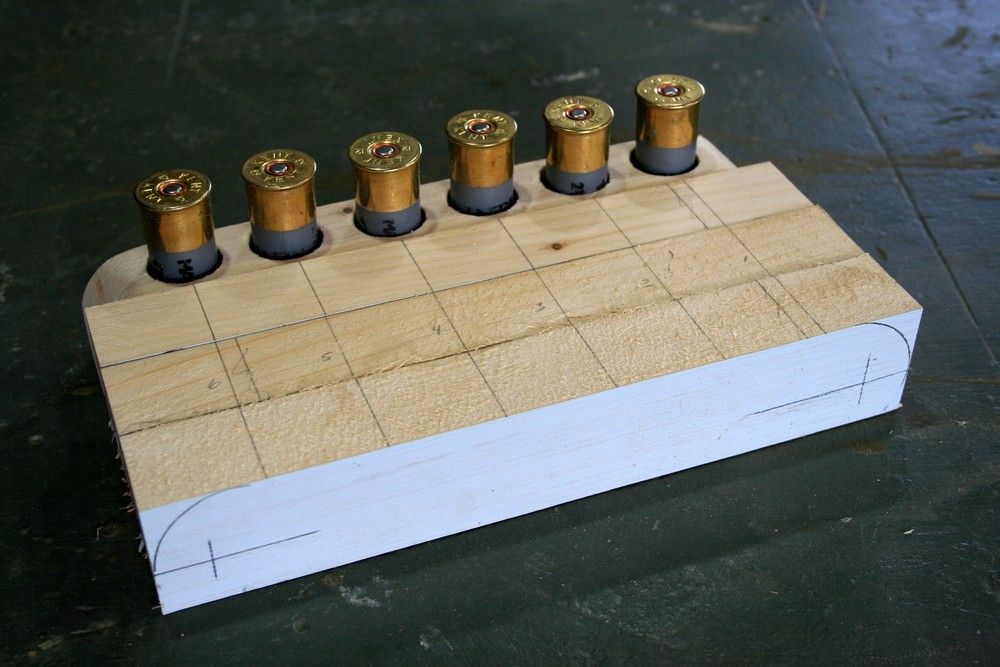

I used a 1/4" Forstner to drill scuppers in each - just in case. I probably should have drilled these before the larger holes.

I used a 1/8" bit for the slip holes for the fasteners - then I countersunk them.

The band saw rounded the corners.

A few seconds on the belt sander...

Then a bit more by hand...

After the duckboat paint dries, it's duck loads on the left and goose loads on the right - ready to install.

All the best,

SJS

Here's a sketch. I used 5/4 White Pine. No magic here - just easy to do when I'm in my own shop - and no out-of-pocket expense.

I made 4 and mass-produced as much as I could. Unlike the factory racks, these allow the bullets to stick up where I can grab them more easily.

I used a 7/8" Forstner bit - but a spade bit would work. I tried 13/16" but it was a bit snug - likely to bind if the wood swelled just a bit. These are for 12 gauge, of course.

I set the fence on my drill press so I stayed on the centerline.

I used a 1/4" Forstner to drill scuppers in each - just in case. I probably should have drilled these before the larger holes.

I used a 1/8" bit for the slip holes for the fasteners - then I countersunk them.

The band saw rounded the corners.

A few seconds on the belt sander...

Then a bit more by hand...

After the duckboat paint dries, it's duck loads on the left and goose loads on the right - ready to install.

All the best,

SJS