Mike Sheppard

Active member

Charlie,

I checked a few local welding shops. The big shop refused to do it because of liability, (they said).

The best small shop around was pretty pricey but probably would have done the best job He was going to heliarc weld the tank but would only take the job on a per hour basis.

The shop I went with had a reputation for getting the job done for a good price. They used a wire fed welder ( I forget the correct terminology, Mig or Tig or something like that.)

The tank was not pretty but has held up well with over a decade of men and dogs stepping on it while picking up decoys in rough water.

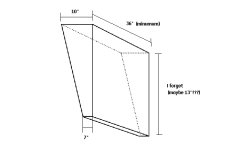

I showed them the space I wanted the tank to occupy and requested 18 gallon fuel capacity. As I stated earlier the tank ended up holding 24 gallon. If space is critical you might want to determine size and capacity yourself before turning the welder loose.

I also asked for a baffle to be welded in the middle to keep the fuel from sloshing around.

They forgot to put one in but I've never really noticed the need for one in actual use.

The tank is made from 1/4" aluminum treadplate and has held up fine.

In hind site I might have went for the heliarc welded tank and the better craftsman but the tank has held up fine and being made of 1/4" aluminum could be easily rewelded by a competent welder if need be.

I chose the location of the tank based on the characteristics of my particular boat. It was light on the front end and would porpoise if not heavily loaded.

The fuel separator is critical to using this big of a tank in my opinion. When I empty the filter every fall there is water in the bottom of the filter.

I bought it from west marine and it uses a mercruiser screw on filter. I just stop in to the dealer and buy a new one every year.

The filter is mounted inside a storage box welded to the boat ribs.

Mike

I checked a few local welding shops. The big shop refused to do it because of liability, (they said).

The best small shop around was pretty pricey but probably would have done the best job He was going to heliarc weld the tank but would only take the job on a per hour basis.

The shop I went with had a reputation for getting the job done for a good price. They used a wire fed welder ( I forget the correct terminology, Mig or Tig or something like that.)

The tank was not pretty but has held up well with over a decade of men and dogs stepping on it while picking up decoys in rough water.

I showed them the space I wanted the tank to occupy and requested 18 gallon fuel capacity. As I stated earlier the tank ended up holding 24 gallon. If space is critical you might want to determine size and capacity yourself before turning the welder loose.

I also asked for a baffle to be welded in the middle to keep the fuel from sloshing around.

They forgot to put one in but I've never really noticed the need for one in actual use.

The tank is made from 1/4" aluminum treadplate and has held up fine.

In hind site I might have went for the heliarc welded tank and the better craftsman but the tank has held up fine and being made of 1/4" aluminum could be easily rewelded by a competent welder if need be.

I chose the location of the tank based on the characteristics of my particular boat. It was light on the front end and would porpoise if not heavily loaded.

The fuel separator is critical to using this big of a tank in my opinion. When I empty the filter every fall there is water in the bottom of the filter.

I bought it from west marine and it uses a mercruiser screw on filter. I just stop in to the dealer and buy a new one every year.

The filter is mounted inside a storage box welded to the boat ribs.

Mike