This is Chad and mine question

Questions are

What is the best way to address this repair?

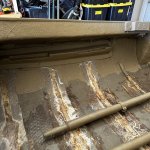

Wow, what a mess. The screws are a tell tale sign a previous owner didn't know what they were doing. Grind out the bad and replace the damaged components. You might even use a sawzall to get those "ribs" out of there. Not hard to do, but dirty work. The right tool for the job will help immensely. A sander/polisher and 3M Stikit Disc Pad, 05568, 8 in, with 80 grit discs will be the fastest and most controllable means to remove the bad glass and prep the hull for new glass.

Interior/Exterior glass? what type? Weight?

Any Special "thickners" interior diab foam etc.?

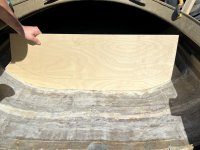

I'd use wood (mahogany or even marine ply) for the new ribs. Epoxy them to the hull and glass them with thickened epoxy (wood flour) fillets using biaxial tape. Probably two layers of 12oz is good, three better, with each layer being wider. 4" and 6" tape. A lot of ways you can do this but the idea is to build rigidity. Even better use the ribs and epoxy a 1/2" floorboard to them. Bevel the edges of the ply to meet the hull. It is a shallow angle. A block plane and some work will get you there. Glass the ply floor with 6 oz woven cloth on both sides. Thickened epoxy around the perimeter and on top of the ribs will secure it. The ribs need to let water flow down the keel so drill holes and seal religiously. Counter bore screws in the floorboard into the ribs and epoxy seal them. You will then tie everything together for a very strong rigid hull. Use thickened epoxy to make the plywood perimeter flow into the hull. The more time you spend on the bevel the better it will look and require less epoxy work.

Glass in stringers, keelsons, strakes?

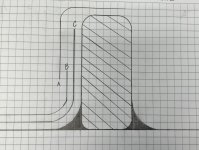

MY preference is parallal but original is perpendicular. The drain hole drilled through the original stiffeners was definitely a weak spot. I'd rather not replicate.

Hell no to the parallel to the keel. You want the supports to run port to starboard, like they originally were. See my above suggestions. If you bond the floor you accomplish strength in every direction. Boats are more prone to flex and crack due to inadequate port to starboard rigidity. Every time you slam a wave the hull wants to "open" more then snap back. That causes the cracks to run parallel to the keel and there is a lot of room for them to grow. I've never seen a crack run port to starboard. Never.