I posted this a while ago, I hope it gives you some ideas. With pic.s

Making a bent, laminated ash sculling oar

Having acquired a new very small scull boat brought up an interesting dilemma. The oars for my larger Merrymeeting Bay float were too long to work well in the small cockpit of the new boat. I borrowed a smaller six foot Joppa style oar which worked much better then my two oars. So I decided to copy this oar. Not being an expert I’m only guessing that the original oar was carved and then steam bent. This seemed to be a bit out of my talent range for a one of a kind (by me) oar. I then looked at simply hogging the oar out of a block of ash but that would have required a 5x5 inch block and a lot of wood removed. Additionally the oar would not follow the grain causing week spots at the bends.

I discussed the project with a hunting buddy who has a full wood working shop and builds furniture as a hobby. He recommended making a laminated oar. By gluing the laminates in the bent shape each layer reinforces the next to hold the bend. In order to straighten out the layers would have to slip with respect to each other. By designing the fixture correctly I could have the laminates follow the centerline of the oar through the bends for maximum strength.

Selecting the wood:

Ash – After a number of discussions on type and the cut of the wood, I went shopping. Ash was selected based on its toughness. This is the wood that baseball bats are made from. Plus it’s the traditional wood for one-piece oars in this part of the country. I debated alternating the ash with mahogany for the aesthetic effect but decided that the oar would end up painted anyway. Straight grain is critical since the wood has to be sliced into 3/16-inch laminates. I located some ¾-inch X 5.75-inch wide X 14-ft + boards, which were pretty straight grain and I compromised. Next time I will try to order the quarter-sawed boards and wait. The less then perfect areas left holes or rough areas when sliced resulting in lost boards. However all were not wasted, as the handle was the only portion requiring the full thickness. This let me use the good portion of the poorer sheets on the handle end.

The wood was prepared by ripping the boards on a band saw with a re-saw blade. The ripped boards were run through a planer. While I was not present for this single step, I understand that it was very noisy due to the toughness and flexibility of the thin wood laminates. It was at this stage the knots came out of the boards. I would like to note that on my next oar I will leave the laminates thicker (1/4” – 5/16”) to simplify the preparation and to reduce the amount of epoxy required.

Epoxy – I used west system but Lou Tisch (Lock Stock & Barrel) has posted that he used Polyurethane one part glue with good effect. Since I used 11 sheets of ash to make the oar, I went through a lot of epoxy. I did put it on heavily but I wanted to insure that I left no voids when I carved out the oar.

Fixture design – This was critical. I wanted to have the same laminate run the centerline of both the blade and handle to provide the strongest oar possible. The fixture had to be strong enough to allow me to clamp 1.75 inches of boards that were all being bent at the same time. I decided that having the 5” wide boards on their sides was the way to go for both simplicity and strength. I’m not sure why, but I elected to keep both of the fixed support boards on the same side of the oar. This worked well for me, and allowed me to stack the laminates on the fixture and simply rotate them up against the support boards. I’m not sure that having the supports on either side wouldn’t have worked as well or even better. Since my method worked, I will write about it based on the two boards being located on the same side.

I started with a heavy baseboard to which I screwed approximately 2x6-inch scrap lumber. The screws came up though the baseboard into the sides of the boards. Make sure to C-sink the holes so the baseboard will sit flat. I attached the board to which I would clamp the handle too first. Then I did so – clamp the handle of my reference oar. The support board ended right where the handle started to curve downward. I then located the flat/straight section of the oar’s blade and marked it on the baseboard (both sides to allow me to find the centerline. And the start of the flat to locate the support board). I then removed the oar, found the oar blade centerline and drew it in. Due to the excess stock, I could not simply locate the blade support board against the oar blade. I had to find the desired centerline and locate the blade support board by adding stock to the centerline. This was the trickiest part of the whole setup. This would need to be done even if you were working from drawn plans.

With the oar removed, I drew the oar handle centerline, parallel to the handle support board spaced out half the expected laminated stock thickness (1-5/8” /2 = 13/16”) – I was planning on ending up with 1-5/8” thick laminated board to shape the oar from. Since this was about ¼” total thicker then the existing oar’s handle the center line would be 1/8” further out then the model oar had been. This is important because the marked center line of the blade has to be offset this amount and then the stock added back in to find the correct location of the blade support board.

Due to its importance, I’ll go though this a bit slower with numbers. The product which will be formed on the fixture is a laminated board 1-5/8” thick by 5.5 inches wide shaped with a couple of curves in it which matched the same blade offset of the original oar. With the desired 1-5/8” thickness of the laminated board the centerline of both the handle and the blade will be offset 13/16” from the support boards. When I marked the model oar on the baseboard the centerlines were based off the finished handle thickness of 1-3/8”, or a centerline offset of 11/16” from the handle support board. To maintain the desired common centerline, while maintaining the original curves in the oar, the new centerline of the laminate must be offset from the original blade centerline by the same 2/16”. Draw this new centerline in. Draw a line parallel to this new centerline, offset to the same side as the handle support board by 13/16”. Using a square, transfer the start of the flat section to the new line. This is the location of the blade support board. Attach it to the baseboard with screws, from underneath.

I left the area between the to flat sections of the oar open. By this I mean that the wood was allowed to form it’s own compound curve rather then my forcing it into a set shape. This seemed to work very well. You will be able to confirm this when you put the first laminate in the fixture – clamp it in place and you will see the curves it forms. This does not mean that this area will not need to be clamped, it will be, but with loose blocks which do not interfere with the curves.

Clamps – I dig up as many clamps as I could get my hands on. They will need to go over 4+” of material (2 blocks and 1-5/8” laminates) and some should be at least 4” deep to clamp the bottom of the laminates. I ended up using 27 clamps for my oar and it was only 7.5-ft long. Cut support blocks 3”x5.5”x at least 1” thick if made out of wood. These blocks are used to spread the clamping force over the full height of the laminate board. I used enough blocks that when positioned side by side, they ran the complete length of the oar. A clamp is needed for each set. Note: a set consisted of one block on each side through the bend area and a single block when in the support board areas of the fixture.

Once everything was assembled, clamps, laminates, blocks, and the fixture, I dry fit everything together. During the dry fit up I determined which laminates I would use and where to position damaged sections so they would not affect the finished product. I clamped it all up, and verified that I had the desired centerlines and that the clamps and blocks would compress the laminates together and evenly squeeze the excess epoxy out of the boards. I then disassembled everything including the fixture. The fixture was wrapped in freezer paper with the waxed surface up/out and stapled in place. The epoxy will not stick to the paper. The fixture was reassembled and another loose sheet of freezer paper positioned over the fixture. This loose sheet was kept around the epoxied ash laminates at all times and the clamps and blocks were always kept outside the paper. This prevented my epoxying the blocks to the oar blank. It also kept me from trashing the fixture and the clamps.

With everything ready the epoxy was mixed and applied to one board at a time and the stack was built up. When the desired thickness was reached the stack (in the freezer paper) was placed against the handle support board, tapped down to line them up evenly, and clamped in a few locations along the board. The laminates were then pull over against the blade support board and clamped fairly loosely at either end to allow the laminates to shift against each other. The middle curved section was then clamped along its length with the 2” blocks. The blade clamps were then tightened and additional clamps added along both the handle and blade. The clamps were snugged down tight a number of rotations as the epoxy was squeezed out. When the clamps stopped tightening the fixture was set off to the side for 72 hours of curing.

Shaping

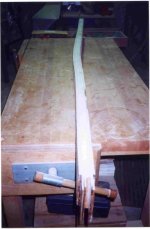

When removed from the fixture I had a 1-5/8 thick board 5.75” wide x 7.5 feet long with the desired curves to made an oar with the same curves as the original. The first step was to run it through the table saw to true up the edges and ends. The reference oar was then traced on the side of the oar blank taking care to keep the centerlines on one laminate. Following these lines the blank was run through the band saw.

The plan view was then traced on the top of the oar blank and cut out on the band saw. From here the shaping was done by hand with drawknife and spoke shave. A router table to turn the handle would have been very nice, well maybe for the next oar. Final work was completed with sandpaper.

The oar was stained and temporarily finished with linseed oil. I say temporarily because I have been reducing the shaft diameter in steps to allow more movement in the oar hole (full-length 2” toilet spud). I will be reducing it further to add a protective / noise dampening leather sleeve.