Scott Farris

Well-known member

Ah, where's the head and galley? Just thinking with that large of a crew there will be needs. Looks SUPER!

Man that is one heck of a blind! Pretty awesome construction.

I see everybody has a job. Good on you to choose "camera guy".Thanks guys. We have built three of this style now, a four, six, and now this eight-man. This one has a rear middle entry while the others were side entry. There is only 5' of headroom so we wanted to enter in the middle so there is less stooping over while you get to your port. You come in and either go left or right to get to your port, instead of walking perhaps the entire length. The entry section is not a shooting port. We are going to put a Blackstone grill in that section because one of our partners is a heck of a good breakfast cook. We still have to add the dog box and stairs, plus sheet metal, etc..

I expect the blind to stand until the posts rot out. All the lumber is treated, but not all treated lumber is the same. I know for a fact the posts that make up my shop are treated to a much greater extent than the posts in this blind. I can't find a local source for .6 UCB 6x6 posts so we simply go with what Lowe's stocks. Having said that I expect these blinds will be around longer than yours truly.

Jeff Smith used to say, "If you don't have time to do it right when will you have time to re-do it?", and that is pretty much the way I feel about projects I tackle. I hate re-rework and repairing things and would rather sink time into the front end of a project while I'm fired up about it, so that is why I go about things the way I do.

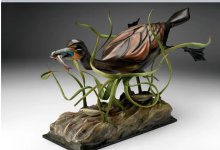

Just finished this up

I'd be proud to put that bench in my dining room!Jode and Vince

Beautiful work!

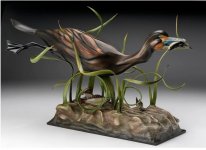

I finished up a few more Bluebills

Also picked up a new workbench to carve on.