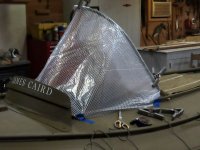

The good news....the bottom is planked.

The bad news....

As I feared, I see no way to complete this boat with a true feather edge. This is entirely due to the use of narrow strips to plank it. There's no way to overhang them enough to come to a "feather". The only thing securing the outside 2 planks is the chine log which has bronze nails in it. I think the edge can be planed down from the deck to maybe 3/4" but I won't know until it's flipped. Someone suggested a fillet to simulate the feather, I'll consider that and the possibility of wrapping a false feather around the chine log. Not the end of the world if it doesn't work out, I bet the ducks won't notice.

The bad news....

As I feared, I see no way to complete this boat with a true feather edge. This is entirely due to the use of narrow strips to plank it. There's no way to overhang them enough to come to a "feather". The only thing securing the outside 2 planks is the chine log which has bronze nails in it. I think the edge can be planed down from the deck to maybe 3/4" but I won't know until it's flipped. Someone suggested a fillet to simulate the feather, I'll consider that and the possibility of wrapping a false feather around the chine log. Not the end of the world if it doesn't work out, I bet the ducks won't notice.