Awhile back I was asking for guidance in choosing a 3D printer. My quest is over, at least for the present time. A good friend of mine upgraded his printer and gifted me his old one, an entry level Creality Ender 3 V2. I have been busy creating a couple simple projects.

First project was some sheaths for some knives I had previously made.

The knives;

With sheaths;

=================================

Second project was an adapter for my crossbow quiver. The factory quiver mount is located on the bottom side of the crossbow. While this has worked for me in the past, I was interested in designing an adapter which would allow the quiver to be mounted above the crossbow limbs.

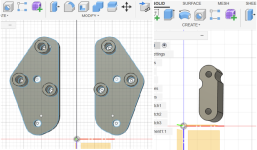

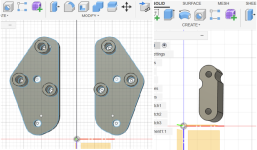

The design;

The printed pieces;

Installed on my Ravin R5;

First project was some sheaths for some knives I had previously made.

The knives;

With sheaths;

=================================

Second project was an adapter for my crossbow quiver. The factory quiver mount is located on the bottom side of the crossbow. While this has worked for me in the past, I was interested in designing an adapter which would allow the quiver to be mounted above the crossbow limbs.

The design;

The printed pieces;

Installed on my Ravin R5;