Richard Lathrop

Active member

Richard Lathrop submitted a new resource:

Adding side planks - Planking Widgeon

Read more about this resource...

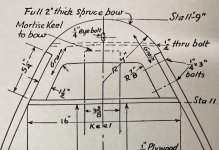

Adding side planks - Planking Widgeon

After setting up the molds, the transom and the bow piece it is time to add the side planks. The plans call for using 3/4" by 8" wide by 12' long planks. My first attempt was to try to use Western Red Cedar boards from Lowes. At 7" wide they were too narrow to fit successfully. I contacted a few local sawmills that advertised cypress planks but they were out of stock.

What I wound up doing was buying 2- 2x10x12 boards in the clearest close to quartersawn as I could. I then planed the...

Read more about this resource...