Steve Sanford

Well-known member

Good morning, All~

I'm not certain how many South Bay Duckboats I have restored and customized in recent years. I have one in the shop right now - and just delivered this one last weekend.

I first saw it half-full of water and with no cockpit cover. All the wooden parts were either gone or rotted to the punky stage.

The vessel itself was sound - and had been built in 1989. The flap boards and mounting blocks were destined for the stove....

The first job was installing a transom drain - which South Bays never had, in my experience - and a new motorboard.

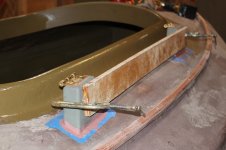

I also molded a new "XL" spray shield - which I developed and made a mold for.

The spray shield gets 2 laminated (Mahogany + epoxy) thatch rails.

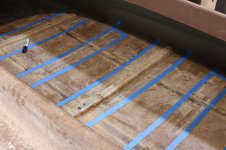

You can also see a new set of floorboards on the left. I am making another set for the current South Bay. I cut the shape with a skilsaw - because the long fair curve is gentle enough. I get a much smoother cut than I would with a sabre saw or band saw.

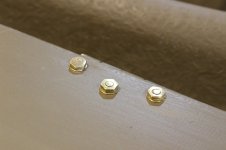

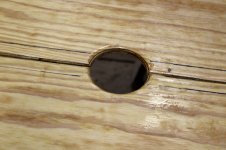

Although I have put scuppers in all of the floorboards I have made or restored, I always cut the hole with a sabre saw. To get a truer circle, I made this jig so I could use a hole saw (3.5"). I made the jig from 3 layers of the same 1/2-inch plywood as the floorboards.

The floorboards get sealed with epoxy - 2 coats on the top before painting.

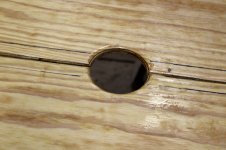

Here is the scupper formed by the paired semi-circles - to allow for a bilge pump should seas - or rain/snow - come aboard.

More to follow.

SJS

I'm not certain how many South Bay Duckboats I have restored and customized in recent years. I have one in the shop right now - and just delivered this one last weekend.

I first saw it half-full of water and with no cockpit cover. All the wooden parts were either gone or rotted to the punky stage.

The vessel itself was sound - and had been built in 1989. The flap boards and mounting blocks were destined for the stove....

The first job was installing a transom drain - which South Bays never had, in my experience - and a new motorboard.

I also molded a new "XL" spray shield - which I developed and made a mold for.

The spray shield gets 2 laminated (Mahogany + epoxy) thatch rails.

You can also see a new set of floorboards on the left. I am making another set for the current South Bay. I cut the shape with a skilsaw - because the long fair curve is gentle enough. I get a much smoother cut than I would with a sabre saw or band saw.

Although I have put scuppers in all of the floorboards I have made or restored, I always cut the hole with a sabre saw. To get a truer circle, I made this jig so I could use a hole saw (3.5"). I made the jig from 3 layers of the same 1/2-inch plywood as the floorboards.

The floorboards get sealed with epoxy - 2 coats on the top before painting.

Here is the scupper formed by the paired semi-circles - to allow for a bilge pump should seas - or rain/snow - come aboard.

More to follow.

SJS