I did this last summer. Getting the top off was easy (only took an hour or two) I drilled out the rivets and was able to get the all but one of the screws out. I used a multi-tool with a caulking removal blade to cut through the places where the original caulking was still holding (not a lot) It did a nice job of cutting the caulk without cutting the fiberglass. My transom was completely rotted so I replaced it with Coosa board. My boat also has the front deck sag and there is really not a good way to fix it short of putting in supports. The floatation foam is really what provides the support and if the deck is sagging, the foam is most likely cracked. The fiberglass on the top lip and at the top of the side of the hull had deformed because of the sag, this was an issue when putting it back together.

My advice IF your transom is solid, would be to not take it apart and to use a bottle jack (with supports) to lift the deck, then put supports in at the front of the floor. I would also flip the boat over and seal under the lip all the way around. The challenge with putting supports in is that the floatation foam covers a good bit of the top so being able to place the supports where they are needed can be a challenge.

there is a thread with what I did on here but feel free to IM me if you want to talk about it.

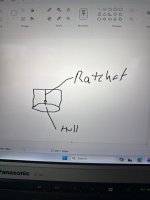

Bottom and top cap

Bottom and top cap

Bottom and top cap

Bottom and top cap