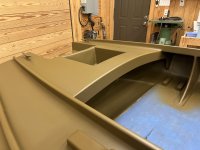

I spent the weekend playing with an idea for my Black Brant I've had for several years. That being adding a rear deck and splash well. With a friends help I was able to cut and fit all the main components that form a 20" front-to-back deck. We put the motor back on the transom and checked clearance. There is some interference if the motor is turned all the way and you raise the tilt to a high position. If you keep the motor straight there is no interference. I don't think this will be an issue. Next step is to disassemble, then sand and prep the areas that will receive epoxy. Then I'll epoxy the components in place and install the deck followed by glassing and finally paint, with a lot of sanding between all of those steps.

I'd love to hear from any Black Brant owners if they think they'd like or dislike a rear deck. My son doesn't like the idea because it removes room preventing a third gunner sitting low in the cockpit and he thinks it will make picking decoys up from the rear of the boat harder. I'm liking the additional storage and place to sit similar to the rear deck on my Broadbill. I'm also liking the idea of greatly reduced chance for a following sea splashing over the transom. The rear deck will eliminate that possibility in any sea I'd ever hunt.

What do you Black Brant owners think?

Eric

I'd love to hear from any Black Brant owners if they think they'd like or dislike a rear deck. My son doesn't like the idea because it removes room preventing a third gunner sitting low in the cockpit and he thinks it will make picking decoys up from the rear of the boat harder. I'm liking the additional storage and place to sit similar to the rear deck on my Broadbill. I'm also liking the idea of greatly reduced chance for a following sea splashing over the transom. The rear deck will eliminate that possibility in any sea I'd ever hunt.

What do you Black Brant owners think?

Eric