It isn’t all that many times in your life that you get to set up a new shop. I’ve been planning my shop setup in WY and this is my first installment. I started with a miter saw station just because that is what I saw myself needing most as we transition to WY. I think I have a pretty solid plan overall. I’ll have a smallsh full shop in the house (heated) and a rough cutting station in the barn with a second miter saw and station to break down panels with the track saw.

I wanted to have the saw be able to cut a 12’er both left and right and this is what I was able to come up with.

For the left cut on a 12’er I’ll have to shoot under the stairs, but that isn’t something I’ll do very often, anyway. I have 8' to the wall now with the access door closed.

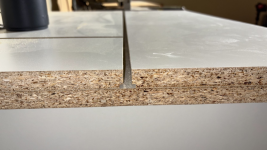

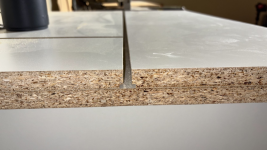

I wanted to have some options for “T” bolts in the surface of the table for either a stop or to extend the fence. Rather than routing in an aluminum t track, I thought it would be fun to shop make the "track" and I liked the control this gave me working the the little bit chippy melamine.

I also thought it would look neat to not have any showing fasteners on the table too, so I mechanically fastened the top from below.

Bought a set of these Amana Tool countersinks, glad I did, they work nice.

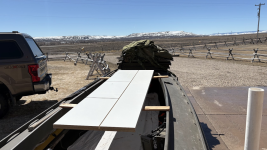

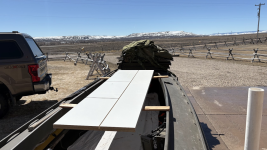

I cut all the stuff in CT and brought it out here. I brought the carcasses unassembled in the truck (23 pieces 24” x 30-31.5”). I’m happy to say that everything worked out well.

Building carcasses.

Pre built tops came in the boat.

I was craving something fun to work on this winter in CT and my other project was a bunch of birdhouses for Mountain Bluebirds (and Violet-green Swallows) here in WY. I was able to get a dozen houses out of a sheet of ACX and some scrap.

Out in the sage.

Success.

I wanted to have the saw be able to cut a 12’er both left and right and this is what I was able to come up with.

For the left cut on a 12’er I’ll have to shoot under the stairs, but that isn’t something I’ll do very often, anyway. I have 8' to the wall now with the access door closed.

I wanted to have some options for “T” bolts in the surface of the table for either a stop or to extend the fence. Rather than routing in an aluminum t track, I thought it would be fun to shop make the "track" and I liked the control this gave me working the the little bit chippy melamine.

I also thought it would look neat to not have any showing fasteners on the table too, so I mechanically fastened the top from below.

Bought a set of these Amana Tool countersinks, glad I did, they work nice.

I cut all the stuff in CT and brought it out here. I brought the carcasses unassembled in the truck (23 pieces 24” x 30-31.5”). I’m happy to say that everything worked out well.

Building carcasses.

Pre built tops came in the boat.

I was craving something fun to work on this winter in CT and my other project was a bunch of birdhouses for Mountain Bluebirds (and Violet-green Swallows) here in WY. I was able to get a dozen houses out of a sheet of ACX and some scrap.

Out in the sage.

Success.

Last edited: