In my layout boat building endeavors-to-be I have considered making a foam core layout. this is ENTIRELY "spitballing"

That said, let's continue

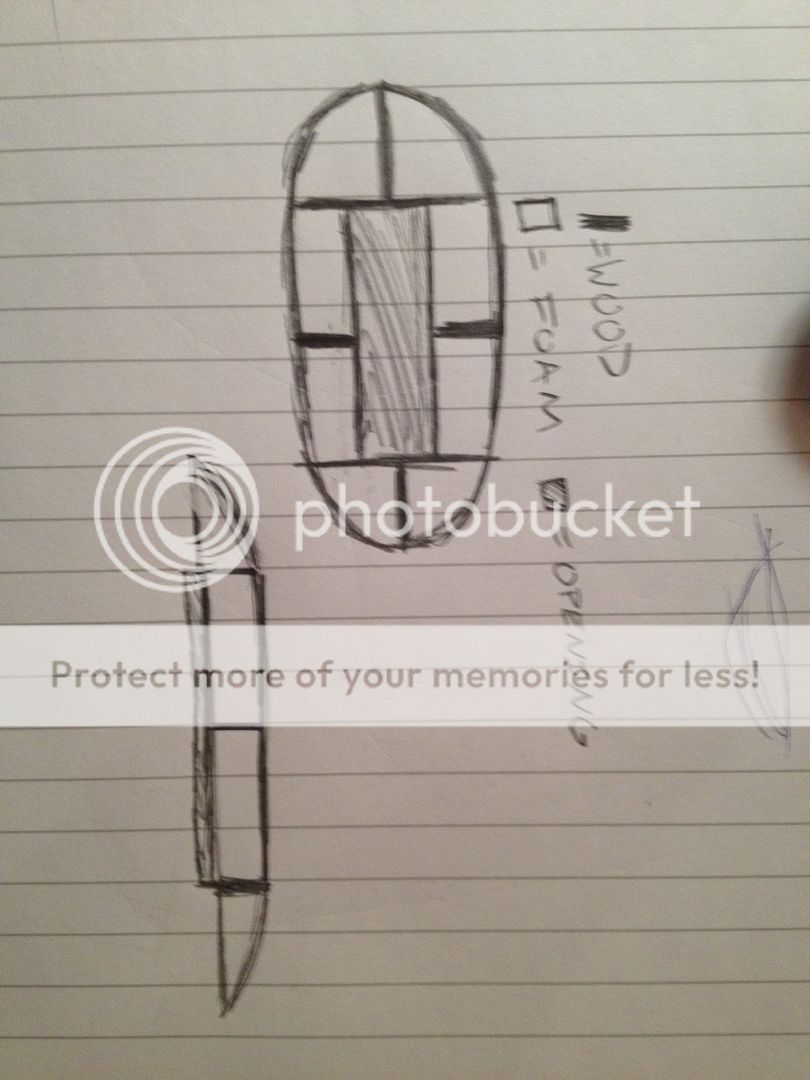

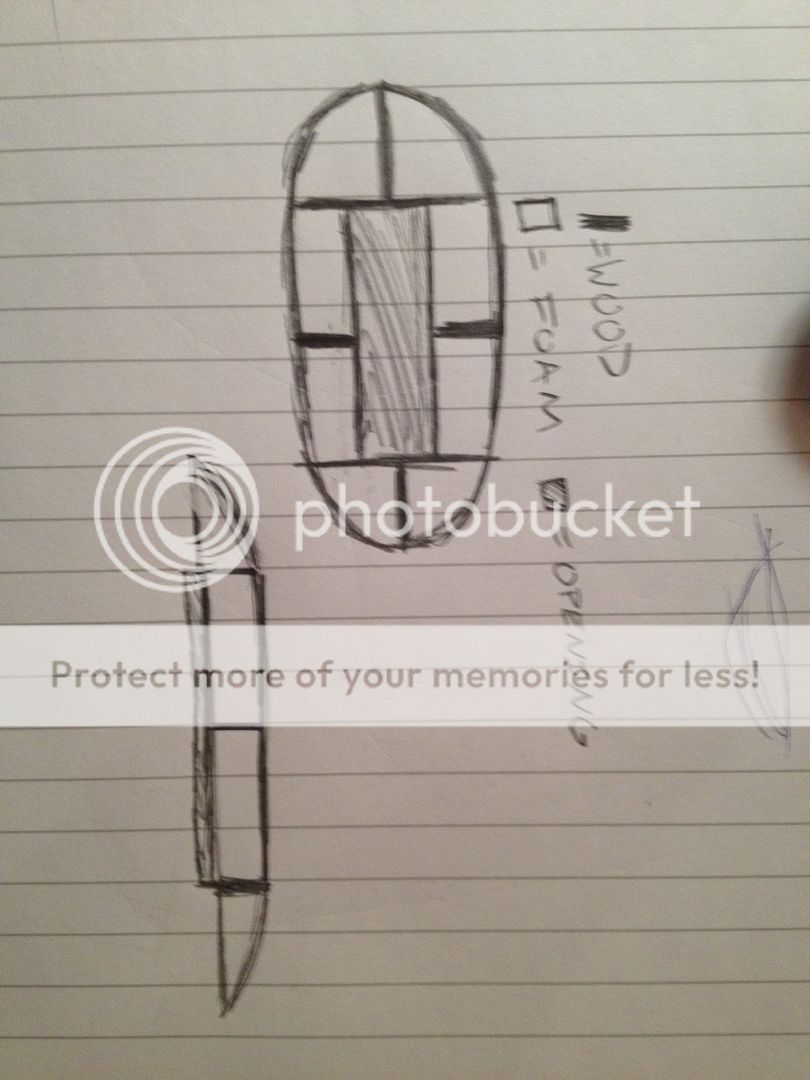

I am considering utilizing a mixture of foam and wood in my next boat project, allowing me to make some crazy curves I couldn't do in ply without going all "Phil" on it and doing kerf cuts etc. I am hoping to make the "shell" this boat largely out of foam by filling all gaps in the main skeletal supports made of ply or lumber. And hey, that way when It breaks and sinks, at least I can hang on and float until hypothermia gets me. (or.... I'm rescued by the tender)

I have lots of leftover of the same glass I used on the bluebill (8oz I think) and plan to use epoxy resin from US composites once again.

Basically a plywood gunners box, with a plywood "floor" supporting all foam from underneath, and supports spanning and supporting that joint from the "box" to the wooden floor.

That said, let's continue

I am considering utilizing a mixture of foam and wood in my next boat project, allowing me to make some crazy curves I couldn't do in ply without going all "Phil" on it and doing kerf cuts etc. I am hoping to make the "shell" this boat largely out of foam by filling all gaps in the main skeletal supports made of ply or lumber. And hey, that way when It breaks and sinks, at least I can hang on and float until hypothermia gets me. (or.... I'm rescued by the tender)

I have lots of leftover of the same glass I used on the bluebill (8oz I think) and plan to use epoxy resin from US composites once again.

Basically a plywood gunners box, with a plywood "floor" supporting all foam from underneath, and supports spanning and supporting that joint from the "box" to the wooden floor.