You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oarlock wood grain orientation

- Thread starter Richard Lathrop

- Start date

Steve Sanford

Well-known member

Richard~

I run my oarlock stanchion grain as you have - parallel to the waterline. Having said that, the check in your White Oak would have me concerned, too.

I generally use thicker stock - 1.5 to 2 inches - and I always bolt my stanchions down through the deck - through a beveled backer block - usually with s/s carriage bolts. The cutout allows water to drain through the socket and down - an important consideration in freezing weather.

BTW: I have used treated lumber (a clear section of 2x SYP), Mahogany, Black Locust. Everything - bolts, sockets, the stanchion-to-deck - all get bedded in 3M 5200.

IF you are making folding oarlocks (as per traditional Barnegat Bay Sneakbox design), you may want to reinforce the Oak with bronze (or even brass) rod.

Hope this helps!

SJS

I run my oarlock stanchion grain as you have - parallel to the waterline. Having said that, the check in your White Oak would have me concerned, too.

I generally use thicker stock - 1.5 to 2 inches - and I always bolt my stanchions down through the deck - through a beveled backer block - usually with s/s carriage bolts. The cutout allows water to drain through the socket and down - an important consideration in freezing weather.

BTW: I have used treated lumber (a clear section of 2x SYP), Mahogany, Black Locust. Everything - bolts, sockets, the stanchion-to-deck - all get bedded in 3M 5200.

IF you are making folding oarlocks (as per traditional Barnegat Bay Sneakbox design), you may want to reinforce the Oak with bronze (or even brass) rod.

Hope this helps!

SJS

Richard Lathrop

Well-known member

Steve,

The widgeon plans have the folding oarlocks using 1” stock.

I was thinking of reinforcing as well.

What source do you use for bronze or brass rod?

On a folding oarlock does the 5/8” dowel in the oarlock remain fixed or is the dowel fixed in the mounts? If it rotates in the oarlock that would prevent running reinforcements from bottom to the top of the oarlock.

Rick Lathrop

The widgeon plans have the folding oarlocks using 1” stock.

I was thinking of reinforcing as well.

What source do you use for bronze or brass rod?

On a folding oarlock does the 5/8” dowel in the oarlock remain fixed or is the dowel fixed in the mounts? If it rotates in the oarlock that would prevent running reinforcements from bottom to the top of the oarlock.

Rick Lathrop

Steve Sanford

Well-known member

Rick~Steve,

The widgeon plans have the folding oarlocks using 1” stock.

I was thinking of reinforcing as well.

What source do you use for bronze or brass rod?

On a folding oarlock does the 5/8” dowel in the oarlock remain fixed or is the dowel fixed in the mounts? If it rotates in the oarlock that would prevent running reinforcements from bottom to the top of the oarlock.

Rick Lathrop

Full disclosure: I am not a fan of folding oarlocks - or even removable pipe stanchions. I cannot believe they have ever resulted in "more birds in the bag" - and - as with anything with moving parts: Danger Ahead! Or - as one old boss used to say: "The juice ain't worth the squeeze. I like simple, sturdy blocks.

Having said that, most Barnegat-style folding oarlocks I have seen have the pins inserted (glued) in the moving part - and swivel in (slightly over-size) sockets on the fixed parts. Thus, your dowels could be short - and go into the Oak 1.5 inches or so. The stiffening rods could then miss the dowels. (And, I would use brass or bronze pins - of smaller diameter - instead of wooden dowels.)

I can get brass rod at my local hardware stores - and bronze from Hamilton Marine:

https://shop.hamiltonmarine.com/products/rod-bronze-solid--by-foot-or-lengths--42544.html

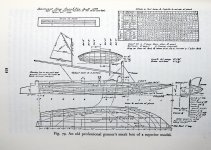

BTW: I notice Chappelle's 1880 Barnegat used metal oarlock stanchions:

A closer look....

Keep up the fine work!

SJS

Steve Sanford

Well-known member

Richard~Is there a preferred wood grain orientation for oar locks. I am building mine out of near quartersawn white oak. Is the grain better parallel to the boat or vertical.

A hairline crack in the oarlock has me wondering.

After pondering the grain-orientation matter further, I found this photo of a VanSant Sneakbox. He solved the splitting problem by using 2 pieces of wood - running in different directions.

This vessel belongs to Jamie Woods. He just had another friend - Mark Mahoney - make a replacement set....

All the best,

SJS

Richard Lathrop

Well-known member

Steven,

Thank you for all the help. I have been using the search feature on the forum to find all past discussions and photos of folding oarlocks. You have been a great help.

Thanks for the assistance.

Rick Lathrop

Thank you for all the help. I have been using the search feature on the forum to find all past discussions and photos of folding oarlocks. You have been a great help.

Thanks for the assistance.

Rick Lathrop

Out of curiosity could marine grade composite dimensional lumber be considered an option for a feature of this nature? Has anybody explored using such materials in certain applications of small craft building? I know we considered using some for a transom replacement on my buddy's 18ft Lund, he ultimately went with two sheets of marine grade plywood.

I haven't used it in a boat setting yet, but I think it could work well for oar locks—likely less prone to splitting compared to wood. However, for other boat applications, it's important to keep in mind that composite dimensional lumber is about 20%–30% heavier than wood. Using it for things like transoms or flooring could add unnecessary weight to the boat overall.Out of curiosity could marine grade composite dimensional lumber be considered an option for a feature of this nature? Has anybody explored using such materials in certain applications of small craft building? I know we considered using some for a transom replacement on my buddy's 18ft Lund, he ultimately went with two sheets of marine grade plywood.

Richard Lathrop

Well-known member

Dave,Out of curiosity could marine grade composite dimensional lumber be considered an option for a feature of this nature? Has anybody explored using such materials in certain applications of small craft building? I know we considered using some for a transom replacement on my buddy's 18ft Lund, he ultimately went with two sheets of marine grade plywood.

I am not sure it would hold to the stress of rowing. Worth testing though.

Rick