Nose and aft boxes are epoxied, fileted, and glassed in, including longitudinal bulkheads in the rear. Still need to make the motor well, but that will come later. I've also fileted and glassed the central hull joint and roughed out a bulkhead to go just in front of the #6 bulkhead, which will allow me to extend the rear deck a little for a seat/poling platform - as well as to tuck away the main battery and house an electrical panel.

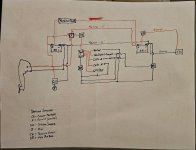

I need to make the #3 bulkhead (had a temporary for the upside down build since I wanted to move it rearward to extend the front deck), then will pull out my pre-build electrical sketches and validate/tweak it for real spaces. I do plan to have space for a second battery for a trolling motor should I decide to add one. Current thinking is it will go under the forward deck just behind bulkead #3 - as will my gas tank, but I want to get it all laid out to confirm. Alternatively it can go opposite the main battery on the starboard side.

Once all that is sorted I can make final adjustments to bulkheads, fix them, and finish internal epoxying. I'd originally thought I'd fix the bulkheads then filet the outer hull to side joints, but looking at it I've realized it will be a lot easier and quicker to do those in long runs and just ease the lower corners of the bulkheads to fit. I can't think of any real downside to that strategy.

I need to make the #3 bulkhead (had a temporary for the upside down build since I wanted to move it rearward to extend the front deck), then will pull out my pre-build electrical sketches and validate/tweak it for real spaces. I do plan to have space for a second battery for a trolling motor should I decide to add one. Current thinking is it will go under the forward deck just behind bulkead #3 - as will my gas tank, but I want to get it all laid out to confirm. Alternatively it can go opposite the main battery on the starboard side.

Once all that is sorted I can make final adjustments to bulkheads, fix them, and finish internal epoxying. I'd originally thought I'd fix the bulkheads then filet the outer hull to side joints, but looking at it I've realized it will be a lot easier and quicker to do those in long runs and just ease the lower corners of the bulkheads to fit. I can't think of any real downside to that strategy.