Sunday evening I loaded my truck and trailer with equipment for moving old iron. I thought about machinery moves I'd made in the past and what was useful. You see, when you extricate machinery by yourself from operations closed many years ago you just never know what you will run into. Just as important as the gear I packed were the lessons I learned years moving heavy machinery with the late Jeff Smith and Bruce Norton.

Yesterday morning I woke at 4:00 a.m. with a full day ahead. By 5:30 I was on the road headed to the extreme NE corner of TN, about 5 1/2 hours away. The goal was to recover a Danckaert spindle moulder that lived decades in a one-man woodworking business. The owner died a number of years ago and the family decided it's time to sell the property including the woodshop.

My hoist and pallet jack were strapped and screwed to the trailer, the cab backseat filled with straps and tools, and the bed carried a nice selection of wood blocks, for I did not know what hurdles the old woodshop would put between the machine and trailer.

After listening to three or four podcasts and some great 80s college rock I was there. I was pleasantly surprised the shop had a sliding barn door wide enough to back my trailer in until the tires hit the slab. There was a wide path from the machine to the trailer. Wow, things are never this easy. All I have to do it lift the shaper with the hoist and roll it to the trailer and set it down. I'll be on the road in less than a half hour.

I rigged lifting straps from the hoist to the shaper and slid the jack handle into the hoist ram and gave her that first pump to take slack from the straps. Then everything fell apart. I mean literally fell apart with hydraulic fluid pouring all over the hoist. The bolt that holds the hydraulic piston assembly together decided to liberate itself somewhere on the 300-mile journey. What came out of my mouth then can best be described as a rainbow of expletives. Miles from nowhere in the foothills of the smokies the chances of finding a store with a new RAM were precisely ZERO. My first thought, after carpet F-bombing the hoist ram and the country that built it, was to pack up drive home empty handed. All that time on the road, packing, fuel, day of vacation burned, would have to be repeated, or simply abandon the shaper. I was furious.

Then I cooled down and decided to problem solve instead of rant. I thought back to the Tannewitz move Bruce and I made and how we got a 3000 lb. machine onto a pallet jack with a crowbar. I repeated the exact same process with the 1400 lb. shaper. Pry a little, slide a wood block under a corner and move to the next. Then put a block under the prybar and repeat the process adding about 3/4" of altitude to the shaper each time around. Sixteen blocks and three inches later she was off the ground enough to slide the pallet jack underneath and roll to the trailer. But I wasn't out of the woods yet. The shaper was a good 10" lower than the trailer even with the pallet jack raised as high as she'd go. So, I repeated the block-up process using the pallet jack to lift the shaper and put blocks under the corners, lower the pallet jack and place blocks on the forks and repeat. By the time I had her level with the trailer I had exhausted every single block at my disposal. But how the hell am I going to slide that mass off the blocks and onto the trailer? I started digging around the old shop and I'll be damned if I didn't uncover a come-along. What a lucky break! Sparing you the details of how a came-along works I'll just say this was the flimsiest piece of crap come-along I've ever seen. I just knew it would break when the line got tight. To my honest surprise the shaper started sliding forward off the blocks and into the trailer. Hell yeah! I'm not coming home empty handed! Three hours after arriving I had the shaper and everything I used neatly secured. I couldn't have done it without Jeff and Bruce.

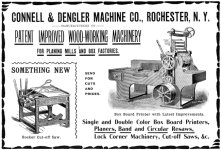

I wish I had pictures of the process, the distance covered, the hurdles jumped, and the tools at hand, but I was on a mission, and it wasn't photography. Instead, I'll share a few pictures from the ad. I think this shaper will clean up nicely and see plenty of use in my shop.

Yesterday morning I woke at 4:00 a.m. with a full day ahead. By 5:30 I was on the road headed to the extreme NE corner of TN, about 5 1/2 hours away. The goal was to recover a Danckaert spindle moulder that lived decades in a one-man woodworking business. The owner died a number of years ago and the family decided it's time to sell the property including the woodshop.

My hoist and pallet jack were strapped and screwed to the trailer, the cab backseat filled with straps and tools, and the bed carried a nice selection of wood blocks, for I did not know what hurdles the old woodshop would put between the machine and trailer.

After listening to three or four podcasts and some great 80s college rock I was there. I was pleasantly surprised the shop had a sliding barn door wide enough to back my trailer in until the tires hit the slab. There was a wide path from the machine to the trailer. Wow, things are never this easy. All I have to do it lift the shaper with the hoist and roll it to the trailer and set it down. I'll be on the road in less than a half hour.

I rigged lifting straps from the hoist to the shaper and slid the jack handle into the hoist ram and gave her that first pump to take slack from the straps. Then everything fell apart. I mean literally fell apart with hydraulic fluid pouring all over the hoist. The bolt that holds the hydraulic piston assembly together decided to liberate itself somewhere on the 300-mile journey. What came out of my mouth then can best be described as a rainbow of expletives. Miles from nowhere in the foothills of the smokies the chances of finding a store with a new RAM were precisely ZERO. My first thought, after carpet F-bombing the hoist ram and the country that built it, was to pack up drive home empty handed. All that time on the road, packing, fuel, day of vacation burned, would have to be repeated, or simply abandon the shaper. I was furious.

Then I cooled down and decided to problem solve instead of rant. I thought back to the Tannewitz move Bruce and I made and how we got a 3000 lb. machine onto a pallet jack with a crowbar. I repeated the exact same process with the 1400 lb. shaper. Pry a little, slide a wood block under a corner and move to the next. Then put a block under the prybar and repeat the process adding about 3/4" of altitude to the shaper each time around. Sixteen blocks and three inches later she was off the ground enough to slide the pallet jack underneath and roll to the trailer. But I wasn't out of the woods yet. The shaper was a good 10" lower than the trailer even with the pallet jack raised as high as she'd go. So, I repeated the block-up process using the pallet jack to lift the shaper and put blocks under the corners, lower the pallet jack and place blocks on the forks and repeat. By the time I had her level with the trailer I had exhausted every single block at my disposal. But how the hell am I going to slide that mass off the blocks and onto the trailer? I started digging around the old shop and I'll be damned if I didn't uncover a come-along. What a lucky break! Sparing you the details of how a came-along works I'll just say this was the flimsiest piece of crap come-along I've ever seen. I just knew it would break when the line got tight. To my honest surprise the shaper started sliding forward off the blocks and into the trailer. Hell yeah! I'm not coming home empty handed! Three hours after arriving I had the shaper and everything I used neatly secured. I couldn't have done it without Jeff and Bruce.

I wish I had pictures of the process, the distance covered, the hurdles jumped, and the tools at hand, but I was on a mission, and it wasn't photography. Instead, I'll share a few pictures from the ad. I think this shaper will clean up nicely and see plenty of use in my shop.