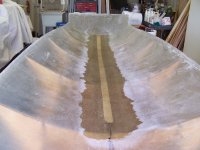

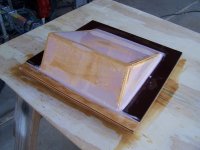

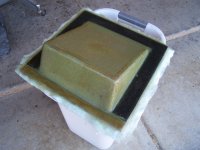

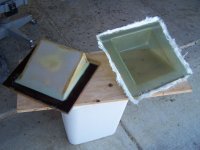

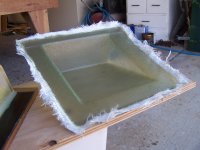

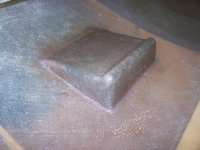

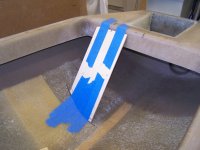

This next step is to bond the deck to the hull. Unfortunately, for some reason I did not take pictures of the first step. Probably, because we had to work fast, to get it done before it set up. Here is how we did it. First we painted the inside of the hull, and the underside of the deck. We used Lou’s FME paint. I like dead grass green. I use his paint on all my boats. I have had scull boats, painted many different colors. I have killed birds with every color. What I have found, in the places that I scull, the green is the most effective. Also, I have made a camo cover for my boat. I use the cover 90 % of the time........ Next, we laid the deck on the hull, then we temporarily screwed the two together at around the edge, at three foot intervals. Once we were satisfied with the fit, it was time to do the bonding. We took it back apart, and bonded the stern first.We used Dyna-glass waterproof fiberglass filler with fibers, to bond the halves This material is like bondo, when it kicks off, you can no longer work it. So we mixed enough to do the stern only. We applied the material, to the pre-marked areas, where the motor well and deck make contact with the hull. We set the deck in place, clamped the area where the motor well makes contact with the transom. Then quickly remove the excess that oozed out. After that was set up, we set up a set of saw horses, making sure they were nice and level with each other. This way the boat, wont get twisted. We then, flipped the boat over.......... Now, Old Leonard started mixing the Dyna-glass in small batches, and I started at the rear of the boat. As each batch was mixed, I would force the mixture down in the shoe box joint. That way we could, do the entire seam, in one continues operation. When I would come to a temporary screw, I would remove it. The material was setting up behind us, so the screws were no longer necessary. We worked our way around the boat, till we completed the job. As we went around the boat, I would take the excess material, and use it to fare out the transition between the deck and hull. After everything was set up, we sanded, an fared out the seam.......... Next, we flipped the boat over and applied two layers of 1 1/2 oz. chopped glass mat over the joint for additional strength. Now it’s an official boat............ We still have lots of work ahead. Since we used a male mold, we have a ton of sanding and faring........... More to come............

This shot shows both hulls.....

This shot shows both hulls.....

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build[ATTACH type="full"]53212[/ATTACH]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build[ATTACH type="full"]53212[/ATTACH]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/004_zps6c72e665.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/004_zps6c72e665.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/005_zpscb1440f4.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/005_zpscb1440f4.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/005_zps629a15db.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/005_zps629a15db.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/007_zpsf92db05a.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/007_zpsf92db05a.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/009_zps0b07da44.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/009_zps0b07da44.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/010_zpsb69fafc3.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/010_zpsb69fafc3.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/011_zpsdfa8e930.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/011_zpsdfa8e930.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/012_zps0013a472.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/012_zps0013a472.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/002_zpsedca378a.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/002_zpsedca378a.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/003_zps7076a693.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/003_zps7076a693.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/005_zpsbd4ecc43.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/005_zpsbd4ecc43.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/006_zps98958904.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/006_zps98958904.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/007_zpsf21371bc.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/007_zpsf21371bc.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/008_zpsb36350de.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/008_zpsb36350de.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/009_zps306eefba.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/009_zps306eefba.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/010_zps6986132e.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/010_zps6986132e.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/011_zps0e56905f.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/011_zps0e56905f.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/012_zps7ecd53ce.jpg.html][URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/012_zps7ecd53ce.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/012_zps7ecd53ce.jpg.html][URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/012_zps7ecd53ce.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/013_zpsf90f0ee2.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/013_zpsf90f0ee2.jpg.html] [URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/014_zps627a2495.jpg.html]

[URL=http://s1258.photobucket.com/user/dcducker/media/scull%20build/014_zps627a2495.jpg.html]