HenryHawthorne

Member

I'm guessing some felt the same about the Titanic!

Terrible thing to say.... yours will stand up to an iceberg much better. you got this, and it will turn out just fine. You got lots of help around here, and even someone rooting you on.I'm guessing some felt the same about the Titanic!

Reviewing the pdf version, just the drawings... but including a drawing for a setup using the bulkheads on a jig for use in building upside down.

Also noted the specs call for 1/2" for hull, chines and deck - did you mention you thought yours were 3/8"? I've sent a note to see if the specs changed over time, and also inquiring about using 3/8". I wouldn't mind saving a little weight in wood, particularly if I'm going to beef up the glass schedule at all.

Good morning, Henry~I've been pouring through the last 5 or so years of posts - so much good stuff here. As I've looked at various builds and experiences with them, I've reflected further on my goals and the reality that I'd need 2 boats to cover 98% of them. While a BB or Cackler may handle 70-80% of them, the more I study the more I realize they occupy the middle ground. As such, I shifted my thinking towards the Snow Goose and Scaup, with a potential Bluebill or Boradbill in the future. Then I noticed the Snow Goose drafts less than BB, Cackler and Scaup - so think that is likely my direction.

A couple questions:

1 - given no boatbuilding experience, would I be better advised to start with a Bluebill or Broadbill to gain building experience before tackling a Snow Goose?

2 - my only personal concerns about building a SG are managing the size/weight during the build process - flipping, etc. I'm sure I can enlist a hand or two at those stages, but how hard are they to manhandle?

Thanks,

Henry

Thanks Steve! I'll be doing most of the work in a shop a friend and I have for working on our cars - part of a small warehouse. Very high "ceilings"... though I am considering designing something by which I could lift the boat off a trailer for storage in the air when off-season/not in use to preserve floor space. I like the round OSB idea for flipping. I have an engine lift (rolling floor "crane") I could easily use to lift and hold the front from the eventual eye hook - and with the OSB idea, or maybe a homemade attachment for my rotating engine stand, flipping by myself would be fairly simple if I can't recruit a few friends.Good morning, Henry~

Two thoughts re flipping your Snow Goose during the build:

1. I have a pair of chain hoists in my shop. IF YOUR CEILING JOISTS ARE STRONG ENOUGH: Is bought my chain hoists from Harbor Freight for ~ $40 each, as I recall. I did not spend 10X as much because my use if infrequent and they live inside (out of the weather).

View attachment 63635

2. With some half-inch OSB and some 2x4s, you could bolt together a pair of circular "cages" to roll the hull over. Un-bolt when she is where you need her.

All that said - a couple of young neighbor farmers - as I have - is awfully handy!

All the best,

SJS

"Eric's offset keelsons to allow water to flow down the lowest point."

I'm not sure what you mean by this. Which boat of mine are you looking at? The way I built my Black Brant is way better than what I did in my Scaup.

This is genius! I worry about what I would find if I had my floor on my havoc aluminum boat lifted.For the longitudinal under the sole, for me it doesn't matter what you do as long as it is done well. My boat drains completely, it only holds the amount of water required to wet the surfaces - it literally won't hold an ounce of water.

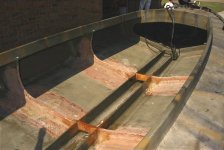

I'd advocate for limber holes on the order of 1 1/2" or 2". Everything under there needs to be built with consideration that it will be the part of the boat that stays wet the most. It is a PITA, but everything under the sole needs to be carefully put together with the intention that it should be easy to seal and stay sealed. For me that means lots of rounded edges that are easy to seal and won't get breached. The limber holes in everything under sole on mine are eased with a roundover bit just like everything else in the boat. I sent you this pic, but I'll put it in here for others. I used a piece of port orford cedar for mine. It is pretty soft wood, too soft for combings, but it is nice to work with, takes epoxy well and is very rot resistant if it coating fails (also smells good).

View attachment 63670

Tod

Nothing to speak of. I have posted the pictures of it, in particular the interior, many times though so Henry might have seen them or can certainly search for them. They are in Scott Gilliland's Broadbill repair thread.

Advice on sneakbox - AA Broadbill or MLB Wigeon

Well, I thought about it a lot. Had a friend come over and look at it and we agreed that the boat would be much mode practical without those frames.... I just cut them out. It looks much better and it is a lot easier to work on. After thinking about it this is what I decided on. I cut out...duckboats.net

That was how I did my Scaup. The above is my Black Brant. Before I sold my Scaup I had to rework the knees into chine-to-chine bulkheads. I call them cockpit cutout bulkheads The trough, as I called it, did allow water to pass but so do limber holes and I think what Tod showed above is a stronger better solution if you use a keelson.I may be mis-using terminology. The plans call for a 1.5" wide keelson between the 3rd and 6th bulkhead - right down the centerline (lowest point side-to-side).

@Eric Patterson - somewhere here I'd seen a picture of a boat with what amounted to 2 longitudinal below the sole, each a couple inches off the keel and mistakenly recalled it being from your Scaup build. Looking at the thread you linked I was obviously wrong, as that doesn't have what I'm calling a keelson at all. I'll dig around and see if I can find it, but after looking at Tod's picture again I'm probably overthinking it and should just stick with the single keelson with lateral limber holes as suggested.