Scott Gilliland

Active member

I've been thinking about a building a steam box -- this look like a great option for a couple of boards.Carpet steamer and 4" pvc worked great for me. Richard View attachment 64932

Thanks

I've been thinking about a building a steam box -- this look like a great option for a couple of boards.Carpet steamer and 4" pvc worked great for me. Richard View attachment 64932

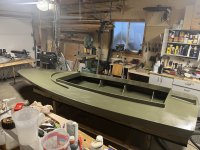

Good decoy shelf and keeps your brushing grass out of the water to a degree when flipped down.Bit more progress. I have the combing on for the spray dodger. The inside of the hull is sanded and just a few more touchups before I can paint the inside of the hull. Made a bit of a mistake with the 5200. I was sure I read that it was sandable somewhere. Left a couple of lumps here and there and it does not appear to be too sandable.

View attachment 65010

I think I will add flapper boards and I'm laying out where the bits and pieces will go. I noticed that the chalks for the flappers are usually quite high and the bottom beveled so the top lays level. I'm thinking about using 3/4 plywood for the chalks. This is a lot lower than I've seen on other boats. I'm guessing this is because my deck is mounted at a lot lower angle than the decks of the other boats. Are there reasons what the flapper boards are usually elevated on chalks? Also, is there a reason that the caulk is beveled on the bottom so the top sits level? I'm thinking it might be so the flapper lays level and you can sit things on it when is down.

View attachment 65012

Scott

Scott,River opened up this week ... earlier than expected. I have a 21' canoe with a 15 Suzuki and I was able to get to the cabin for the weekend. I'd hoped to make that trip in the BlueBill. For now, I will use the 15 Suzuki. I might convert it to a 20 hp, but I'll wait and see how it handles with the 15.

This one is not a Devlin design... it was a home built from a ClarksCraft (https://www.clarkcraft.com/cgi-loca...2352&cart_id=c0bf8e7cd28a0fbaf7f2313f1183450e.) Unfortunately, I cannot tell you how it handles. I bought it second hand last fall to hunt it. I put it on the water and made a very quick run - maybe 5 minutes. It handled very well and it felt good on the water... That's all I can tell you. I brought it home and the floor boards were attached to the frames. We have a lot of mug and sand here and I did not like that setup so I removed the floor boards thinking I'd figure out a way to make them removable. Removing the floorboards revealed serious problems. There were several large sections of the plywood hull that were saturated with water. This required a rebuild of the hull.Scott,

How do you like your Bluebill? Seems not too many have built or own this Devlin design. Have the study plans, but still mulling it over before committing myself. Richard

you can, I did, but it is not strong. If you step on it, it will break. I am now a BIG fan of using webbing.Another question. I'm copying Steve Sanford's use of pvc trim boards for the rail that holds the bottom of the spray dodger. I'm wondering if I ripped it down to 1/2" if pvc trim boards could be used for grassing rails. I was thinking about using webbing, but I like the look of the rails better. Any thoughts?

I would lay out all the holes. Then come back, excuvate the foam with the drill, swirl it around to make a cavity. Fill the cavity with thickened epoxy. After cured, predrill for the mounting screws.Dave/Roy,

I went with plastic lumber. It is not composite deck material, but solid plastic decking. I made the sections for grassing 8" long by 1/4" high. I don't think you can break it -- it has a bit go give, but very little over 8". If it does not work, I will use webbing. I'n struggling with attachment now. The front section of the deck is completely enclosed with 1/4" plywood and filled with floatation. The first 4 screws of the rails fall in this section of the deck and I have no way to attach a backer. I'm testing out a method using an epoxy saturated piece of sponge squished into a hole 4x the size of the screw. I have to wait until tomorrow to see how the epoxy sets up. If this does not work I may resort to these hollow door anchors that are designed for 1/4" material (https://toggler.com/products/toggler-plastic-toggle-anchors). Any other ideas?

View attachment 65159