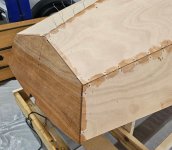

Pulled stitches from the nose - all seems quite solid. But decided I'd go ahead and fillet and glass them front and rear transoms and the sides of the nearest bulkhead. I'd do that before flipping regardless, so why not now? I started on the front knowing it would be the most difficult to get to - lots of sliding under the frame to pull up in a tight space.

View attachment 65317

View attachment 65318

Of course, that resulted in epoxy in my hair, presumably from drips on the plastic. I probably need to get a gallon of vinegar for the shop - not sure multiple acetone head scrubs would be good for my health. But a light rubbing then a sink/Go-Jo head wash seems to have gotten it all out.

Will get on the aft transom in the next few days - with both done, I'm confident the panels will stay in place for sanding and sheathing and sanding and completing the bottom.

I'm planning to tape the outside seams in addition to sheathing - I've noted Sam recommends sheathing first and see others here have done it in that order. Is there a reason for that versus taping first and using the sheathing to cover the tape seams? I plan to sheath dry, so would let the epoxied tape cure and sand lightly before sheathing.