Always good to look sharp in your boat.

I should have written "narrow 1/2 round bronze keel protector". Still can't make up my mind.

I should have written "narrow 1/2 round bronze keel protector". Still can't make up my mind.

In the photo they're clamped down. They wanted to spring back. My technique to minimize the springback is to add bend during final assembly. The planks will be epoxied and screwed down to the removable timbers. When that happens, I place a large weight in the middle to hold it down....a 50 lb bag of corn (or 2) usually works.....then place a 2x4 under the ends to build in a little extra bend while the epoxy sets. Rarely does it result in enough permanent bend, but it helps. Depending on how much springback remains, a couple of rotating cleats may be required. Tough to predict.SJ,

Enjoying your build. How did you get your floorboards to lay against the bottom with the bottom rocker?

Rick Lathrop

SJ~In the photo they're clamped down. They wanted to spring back. My technique to minimize the springback is to add bend during final assembly. The planks will be epoxied and screwed down to the removable timbers. When that happens, I place a large weight in the middle to hold it down....a 50 lb bag of corn (or 2) usually works.....then place a 2x4 under the ends to build in a little extra bend while the epoxy sets. Rarely does it result in enough permanent bend, but it helps. Depending on how much springback remains, a couple of rotating cleats may be required. Tough to predict.

Thank you. Your work looks great. My boats don't approach yours in fit and finish. Maybe if I ever get my butt into retirement I'll be willing to spend the extra time.SJ~

Whilst you were answering, I was searching through my photos on "floorboards" and "turnbuttons".

One thing I have done with springy floorboards is to hold them down amidships with turnbuttons. I typically use Locust - but I have also seen some very nice ones cast from bronze. (Brass would probably work...)

In my RED-LEG (Barnegat) - the central floorboard is screwed in pace - but the laterals are removable via turnbuttons: (photo is 2016 pre-restoration).

View attachment 68930

I cannot locate my photos, but for a one-piece slatted floorboard, I fasten a pair of turnbuttons to the ribs, either side amidships.

In my old gaff sloop WILLET - long before digital cameras - the center floorboard was held down by turnbuttons that sat below flush in shallow "sockets" - on the seam between both attached laterals and the free central board.

On my usual plywood floorboards - as for the South Bay I am working on right now - the turnbutton turns on a pad that is almost flush with the floorboard:

View attachment 68931

I am thoroughly enjoying your work!

All the best,

SJS

Steven,SJ~

Whilst you were answering, I was searching through my photos on "floorboards" and "turnbuttons".

One thing I have done with springy floorboards is to hold them down amidships with turnbuttons. I typically use Locust - but I have also seen some very nice ones cast from bronze. (Brass would probably work...)

In my RED-LEG (Barnegat) - the central floorboard is screwed in pace - but the laterals are removable via turnbuttons: (photo is 2016 pre-restoration).

View attachment 68930

I cannot locate my photos, but for a one-piece slatted floorboard, I fasten a pair of turnbuttons to the ribs, either side amidships.

In my old gaff sloop WILLET - long before digital cameras - the center floorboard was held down by turnbuttons that sat below flush in shallow "sockets" - on the seam between both attached laterals and the free central board.

On my usual plywood floorboards - as for the South Bay I am working on right now - the turnbutton turns on a pad that is almost flush with the floorboard:

View attachment 68931

I am thoroughly enjoying your work!

All the best,

SJS

Got a photo? Those sound nice.Steven,

My work will not be at your level but I copied your turnbuttons. I initially used some oak half round but didn't like the feeling when sitting on them so I ordered some brass half oval from OnlineMetals and I made brass turnbuttons.

Rick Lathrop

Thanks.Looking good? How's the poison ivy?

I like those. Ill see if I can make one work in this boat. Like you, I enjoy comfort. I put a piece of memory foam on my backrests. The first iteration was a leftover from an old mattress heading to the dump.Good morning, SJ~

Truly wonderful work - congratulations once again!

Here is one more idea for you. In my Dad's Great South Bay Scooter - built by Benjamin Hallock, probably in the 1920s - the backrest doubles as a rowing bench. The bench gets you up about 5 inches off the floorboards AND - whether by careful design or sheer serendipity - it wedges just under the forward coaming so it always provides a comfortable angle for your head, neck and upper back whilst you are lying in wait.

View attachment 69025

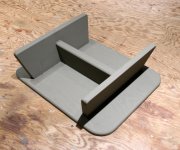

Given the varying geometries, such a combination is not always possible - but it is worth it if you can do it. Here is the underside of another - made a bit wider for a bit more comfort.

View attachment 69026

And, on my more recent backrest/benches I have succumbed to comfort and glued on some 1/2-inch foam (shop mat)....

All the best,

SJS