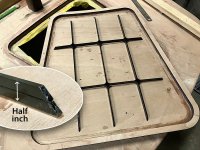

At the moment I'm working on the lid for the anchor well.

It's 2 layers of 6mm (1/4-inch) Gaboon plywood and I want to be able to stand on it, even step down off a dock onto it without it flexing.

I'm not sure if a couple layers of glass inside and out will increase its rigidity enough and thought it probably needs some sort of webbing on its underside.

At work we just laser cut a bunch of acrylic plaques, and looking at the waste got me thinking! (insert eye roll)

What if I glass in the acrylic waste, double stacked, as webbing to the underside of the lid? I'd probably have to vacuum bag it.

Is this a valid idea or should I make some sort of webbing or stiffening batton from plywood instead?

Lid is about 19.5" long by 15.5" wide.

If it was your boat, how would you make it? What's the best way to get the lid super rigid?

Last edited: