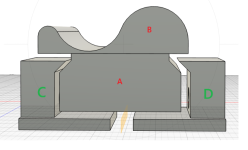

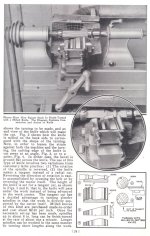

I want to duplicate the pictured set-up on my lathe or come up with something similar. Right now I'm lacking the milled-to-pattern cutter but have a vendor who can supply them. I have the cross slide to mount the cutter to. I don't have the tool holding device nor have I done a lot of metal lathe set-up and could use some help in this arena.

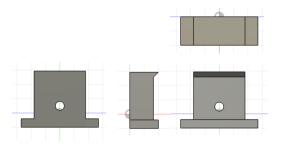

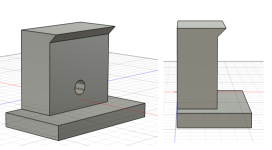

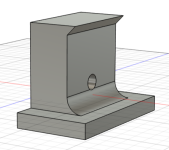

Looking at the tool holding device it appears to utilize the cross slide's t-slot that runs left to right and has a bolt to clamp the cutter in place. The "lugs", for lack of a better term, have a bevel that I assume applies downward pressure to jam the cutter flush on the cross slide's face preventing it from moving. Other than that I'm not real sure. It looks like each lug is attached to its own bar stock that rides in the T-slot and are drawn together with a bolt. I.e. separate left side and right side with a bolt that pulls it all together. I'm not sure how the lugs are attached to the bar stock. Maybe they are milled from a single piece.

Any thoughts on this, or other ideas on how to attach the milled-to-pattern cutter to the cross slide? Maybe the simplest and easiest means is to counterbore the cutter and use a bolt and T-nut to lock it in place.

Thanks.

Looking at the tool holding device it appears to utilize the cross slide's t-slot that runs left to right and has a bolt to clamp the cutter in place. The "lugs", for lack of a better term, have a bevel that I assume applies downward pressure to jam the cutter flush on the cross slide's face preventing it from moving. Other than that I'm not real sure. It looks like each lug is attached to its own bar stock that rides in the T-slot and are drawn together with a bolt. I.e. separate left side and right side with a bolt that pulls it all together. I'm not sure how the lugs are attached to the bar stock. Maybe they are milled from a single piece.

Any thoughts on this, or other ideas on how to attach the milled-to-pattern cutter to the cross slide? Maybe the simplest and easiest means is to counterbore the cutter and use a bolt and T-nut to lock it in place.

Thanks.