Tom Barb

Active member

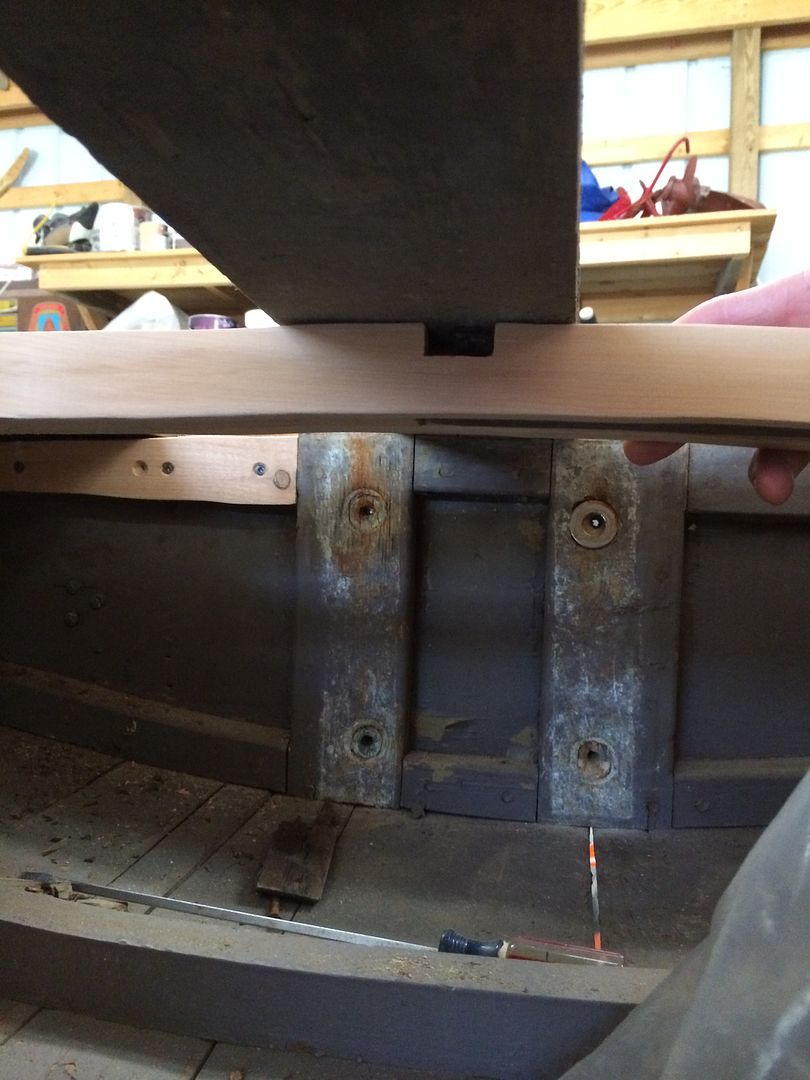

STILL in the process of refurbishing my old Sneakbox. I'm to the point where I'm replacing my gussets connecting the top ribs and bottom ribs. I got a piece of 1/2 inch okoume. The hull ribs are 2 piece so I'll be sistering 1/2 cedar for connecting these because these will most likely see the most water.

My question is do I need to coat the gussets in epoxy before I install them? It is okoume so is supposed to be glued together with waterproof glue. The boat will be stored inside so it shouldn't see fresh water. Even hunting, I wouldn't think they would see much water. Maybe a few splashes.

The original gussets were just regular 3/8 plywood and weren't in terrible shape. Seems they lasted for over 60 years.

My question is do I need to coat the gussets in epoxy before I install them? It is okoume so is supposed to be glued together with waterproof glue. The boat will be stored inside so it shouldn't see fresh water. Even hunting, I wouldn't think they would see much water. Maybe a few splashes.

The original gussets were just regular 3/8 plywood and weren't in terrible shape. Seems they lasted for over 60 years.