With 2 new grandchildren in 2021, and 2 more in 2023, I suspect this might be the last 1 man boat I mess with. As you already know, I found a SBDB back in March, and have been doodling a plan for a couple months. Last week I took a "ME" week of PTO. No fixed agenda, just a week to do what I needed and wanted to do. It did include chores, cutting grass, servicing the lawn tractor, new brakes, headlights and a power steering reservoir on Maria's car, and washing both her car and my truck. I also got to see Mom and the rest of the family and each of the children and grandchildren.

And I got to tear into the SBDB!

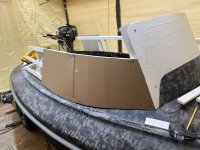

The first order was to replace the motorboard, which was too short for my yamaha. Following Steve's tutorials, I shaped a very nice piece of mahogany.

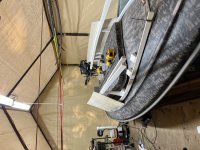

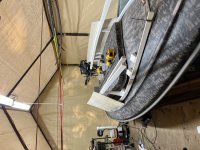

Then it was onto working through the blind. Brian Garman has been using a cut down milk crate and a layout seat. He commented that he wished it had some dry storage included and that the seat was fixed to the crate somehow. So I though about how I might address both of those needs. My first thought was to cut down one of the dove/deer seats that I have, the kind that is the square cooler bucket with the swivel seat. So I searched for a deal on one, but they were more than I wanted to spend to cut it up. Then I thought about the Harbor Freight "Pelican" cases. In the long run, I spent more putting this together, but it is more dry storage, and is more stable than the other seat would have been.

While I will sit higher than Brian does, I find it comfortable and fits within the cockpit reasonably well.

Having now establishing the seat height, I can work on the blind.

My ground rules for the blind were:

1. allow for the use of the original cockpit cover

2. allow for the use of the original navy dodger/canvas

3. minimize weight

4. minimize maintenance by using PVC and FRP in place of any wood products

5. minimize the damage to the original hull, limit holes and perform no cuts

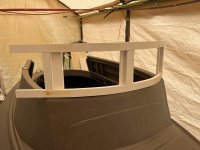

So I started working with a bunch of PVC trim and framed out the Starboard side with 1x2s

I utilized the original flap board holes for 2 of the 3 mounts on each side.

I also added some FRP to the Spray Sheild

Continued......

</html

And I got to tear into the SBDB!

The first order was to replace the motorboard, which was too short for my yamaha. Following Steve's tutorials, I shaped a very nice piece of mahogany.

Then it was onto working through the blind. Brian Garman has been using a cut down milk crate and a layout seat. He commented that he wished it had some dry storage included and that the seat was fixed to the crate somehow. So I though about how I might address both of those needs. My first thought was to cut down one of the dove/deer seats that I have, the kind that is the square cooler bucket with the swivel seat. So I searched for a deal on one, but they were more than I wanted to spend to cut it up. Then I thought about the Harbor Freight "Pelican" cases. In the long run, I spent more putting this together, but it is more dry storage, and is more stable than the other seat would have been.

While I will sit higher than Brian does, I find it comfortable and fits within the cockpit reasonably well.

Having now establishing the seat height, I can work on the blind.

My ground rules for the blind were:

1. allow for the use of the original cockpit cover

2. allow for the use of the original navy dodger/canvas

3. minimize weight

4. minimize maintenance by using PVC and FRP in place of any wood products

5. minimize the damage to the original hull, limit holes and perform no cuts

So I started working with a bunch of PVC trim and framed out the Starboard side with 1x2s

I utilized the original flap board holes for 2 of the 3 mounts on each side.

I also added some FRP to the Spray Sheild

Continued......

</html

Last edited: