Steve Sanford

Well-known member

All~

Tom Barb just asked me about the "XL Spray Shields" I have been making for many years now. So, I thought I would give an overview here. This does not depict the full step-by-step building process.

It is based on the stock spray shield from the South Bay Duckboat (brainchild of Red Magnus and Ray Milliken, circa late 1960s). The XL is both taller and wider than the original.

Yes, the force fields are humming menacingly at the vessel levitates here at Pencil Brook Boatworks.... Much more hide (for a sitting gunner) and more protection from errant seas.

Here it is on a South Bay. It extends rail-to-rail on deck.

Here it is with polypropylene webbing - instead of the traditional laminated wooden rails.

Here it is on a Duck Invader. I have been happily surprised to see how many different gunning boats it fits. Anything near 3 or 4 inches of crown in 4 or 5 feet of beam seems to work.

Note the shield is fairly vertical because of the flatter deck.

Here it is on a Duck Wrangler. Almost no rake - but still effective.

I built the mold about 10 or 12 years ago. The main shield is easy; the flange requires more demanding woodworking. Frame is 1/2-inch AC plywood and the sheathing is tempered Masonite (MDF). The joint between shield and flange is filled and faired - followed by sealing, priming and 2 topcoats of gloss enamel. Making sure the fiberglass does not stick can be done with cellophane packing tape - or mold release wax.

I wax several times then brush or spray on a film.

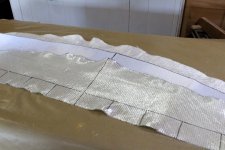

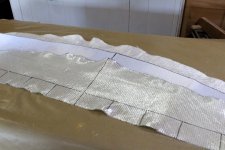

Layup is: 1708 biaxial with mat - 2mm Coremat - 1708 biaxial with mat. I stagger the flange cuts on the biaxial layers - and cut a separate strip of the Coremat for for the flange - rather than struggle with the bend during the layup and saturation.

Resin is polyester. The less expensive polyester resin is better than epoxy when the laminates are all plastics. (i.e., no wood) But, I do not use it in the shop (health and persistent fumes) - so I only make these shields during the warmer months when I can work outside.

Once saturated, the shield usually hardens within an hour. Nevertheless, I let it bake in the sun and leave it on the mold overnight.

Of course, the shield is a bit oversize and so needs trimming.

I usually pop it off slowly - starting with a putty knife or softwood wedges. Trimming involves a variety of saws and sanders. I wear leather gloves during the early handling because of the very sharp 'glass splinters. (It is not a fun part of the job....)

I use the same mold for laminating wooden thatch rails. I add the spacers to the rails after they are off the mold. (Sorry for the out-of-focus!)

I make these as stand-alone parts - when I am not doing a full restoration on a vessel. If you want to make your own mold, I can take a few dimensions that can help you design one.

All the best,

SJS

Tom Barb just asked me about the "XL Spray Shields" I have been making for many years now. So, I thought I would give an overview here. This does not depict the full step-by-step building process.

It is based on the stock spray shield from the South Bay Duckboat (brainchild of Red Magnus and Ray Milliken, circa late 1960s). The XL is both taller and wider than the original.

Yes, the force fields are humming menacingly at the vessel levitates here at Pencil Brook Boatworks.... Much more hide (for a sitting gunner) and more protection from errant seas.

Here it is on a South Bay. It extends rail-to-rail on deck.

Here it is with polypropylene webbing - instead of the traditional laminated wooden rails.

Here it is on a Duck Invader. I have been happily surprised to see how many different gunning boats it fits. Anything near 3 or 4 inches of crown in 4 or 5 feet of beam seems to work.

Note the shield is fairly vertical because of the flatter deck.

Here it is on a Duck Wrangler. Almost no rake - but still effective.

I built the mold about 10 or 12 years ago. The main shield is easy; the flange requires more demanding woodworking. Frame is 1/2-inch AC plywood and the sheathing is tempered Masonite (MDF). The joint between shield and flange is filled and faired - followed by sealing, priming and 2 topcoats of gloss enamel. Making sure the fiberglass does not stick can be done with cellophane packing tape - or mold release wax.

I wax several times then brush or spray on a film.

Layup is: 1708 biaxial with mat - 2mm Coremat - 1708 biaxial with mat. I stagger the flange cuts on the biaxial layers - and cut a separate strip of the Coremat for for the flange - rather than struggle with the bend during the layup and saturation.

Resin is polyester. The less expensive polyester resin is better than epoxy when the laminates are all plastics. (i.e., no wood) But, I do not use it in the shop (health and persistent fumes) - so I only make these shields during the warmer months when I can work outside.

Once saturated, the shield usually hardens within an hour. Nevertheless, I let it bake in the sun and leave it on the mold overnight.

Of course, the shield is a bit oversize and so needs trimming.

I usually pop it off slowly - starting with a putty knife or softwood wedges. Trimming involves a variety of saws and sanders. I wear leather gloves during the early handling because of the very sharp 'glass splinters. (It is not a fun part of the job....)

I use the same mold for laminating wooden thatch rails. I add the spacers to the rails after they are off the mold. (Sorry for the out-of-focus!)

I make these as stand-alone parts - when I am not doing a full restoration on a vessel. If you want to make your own mold, I can take a few dimensions that can help you design one.

All the best,

SJS

Last edited: