You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zach Taylor widgeon by mighty layout boys HELP

- Thread starter Dylan N

- Start date

Dylan N

New member

Which foam core is best coosa board, kerdyn,divinycell?Those "square bumps" are the original Divinycell structural foam put in when the hull was originally fiberglassed using polyester, a chopper gun and a mold. Mark was all about weight, at the expense of durability and strength. Adding a foam core between the existing hull and any additional layers will provide much more rigidity than just adding more layers of glass.

Eric is 100% correct in his advice to NOT use polyester resin, and yes you need to get to bare fiberglass, no paint.

Can't really offer an opinion, you will need to ask others, research, compare, and make your own decision.Which foam core is best coosa board, kerdyn,divinycell?

I have an MLB Chuck Huff. I believe Dave does too? It's a bit bigger than your widgeon and is rated for up to 15hp.

The earlier Chuck Huff models had floor flexing problems and some even developed cracks and leaked. I believe there are threads documenting the early problems and solutions. Adding the foam core, as Dave and Eric have suggested, was the factory solution to the flexing issues. Mine has, what appears to be, a thin 1/2" ish thick core layer glassed on top of the boat floor/bottom.

With a 15hp motor, empty, my little boat runs around 26mph and there are virtually no flex issues. If I run perpendicular across large chop, you see a bit of movement but nothing that is concerning or worrisome. If I were you, I'd look hard into the foam core solution.

The earlier Chuck Huff models had floor flexing problems and some even developed cracks and leaked. I believe there are threads documenting the early problems and solutions. Adding the foam core, as Dave and Eric have suggested, was the factory solution to the flexing issues. Mine has, what appears to be, a thin 1/2" ish thick core layer glassed on top of the boat floor/bottom.

With a 15hp motor, empty, my little boat runs around 26mph and there are virtually no flex issues. If I run perpendicular across large chop, you see a bit of movement but nothing that is concerning or worrisome. If I were you, I'd look hard into the foam core solution.

Steve Sanford

Well-known member

Dylan~Pictures below, I have just purchased a Zach Taylor widgeon made by the layout boys. I was told that it was a great dual purpose hull. I was told I could get the best advice on this forum. I have a couple questions any info personal input or advice on this boat would be appreciated. I plan to solo when everyone bails on me and then late season layout maybe with my tender and buddies.

The hull should be all fiberglass with NO wood is that correct that’s what it seems like to me?

The floor seems to have a little flex to it one half more than the other. To add strength can I just sand the paint off with 80grit and use 2 layers 1708 fiberglass and epoxy resin on underside and inside then hit it with 120 and paint?

how did the top mate to the hull from factory or what should I do. Someone caulked it and it lets water in where they meet. Should I glass it shut or 4200 seal it? Suggestions?

The square hole the lip seems not as strong as I’d like for someone my size 6’1 265lb can I do the same thing with 1708 I’m asking cause I’ve never worked glass much before.

I’d love to find oar mounts someone took them off and what length oars to use or do u guys just kayak row?

I got the boat and trailer for $700 hopefully I did ok. Going to put a 8hp Yamaha on it.

Thank you

View attachment 56805View attachment 56806View attachment 56807View attachment 56808View attachment 56809View attachment 56810

I have not worked on this vessel. I have, however, stiffened floors on numerous South Bay Duckboats whose floors are notorious for oil-canning. I add additional floors - and reinforce the existing ones. I use PVC "lumber for the frames and 1708 for both the new frames and the existing. I mill the PVC to a trapezoidal section on my table saw:

Here are both old and new - with the 1708 set in epoxy.

Having said that, the Divinycell suggestion sounds like a fine fix.

All the best,

SJS

Dylan N

New member

Thanks Steve great ideaDylan~

I have not worked on this vessel. I have, however, stiffened floors on numerous South Bay Duckboats whose floors are notorious for oil-canning. I add additional floors - and reinforce the existing ones. I use PVC "lumber for the frames and 1708 for both the new frames and the existing. I mill the PVC to a trapezoidal section on my table saw:

View attachment 57527

Here are both old and new - with the 1708 set in epoxy.

View attachment 57529

Having said that, the Divinycell suggestion sounds like a fine fix.

All the best,

SJS

Dylan N

New member

This thread has been of what I noticed as visual and feel when I bought the boat but now I finally put the boat in the shop and started diving into it. Here’s what I have found and now have physical evidence. But I would like to be told what the hell to do now. The floor is to what looks like to me. Glass at the hull then closed foam of some sort then mat glass on top with a dusting of paint. In the pictures u will see the oil can feeling from pushing on it come to find out is the thin void where the closed cell foam is moving to hit the hull. Also seems like a piece was ram down the bottom below that like a spine. So water went through the mat and into that foam area. I sucked as much out with my vacuum pump fluid extractor (for cars). But what now. Do I have to grind the edges and remove all this and start over. Or just put my 1708 layer over this and epoxy it? Do I try injecting thickened epoxy into the void…..? Also the combing come to find out actually does have plywood standing on edge Inside. Do I saw the top off and replace with closed cell foam or just fill it with thickened epoxy and run a strip of 1708 over it? When I pushed the silicone out of holes someone filled. It looked like the top of the boat is made of a core of that closed cell looking foam.

Attachments

Dylan

I am not a fan of patching over damaged or weak areas. I approach things as I can do better than the original builder because look at how his work held up. Looking at your pictures I would tear out any damaged areas and get back to good solid glass and then build back. Once you make up your mind to get destructive the tear down will go faster than you think. It looks to me like you can cut the floor out, put some foam pink board down with all the hard edges rounded over, and glass over the top several times to rebuild a sturdy floor. For the coaming I would dig out all that flaky loose looking stuff and see if I could cut some wood pieces to epoxy back in, filling all voids, and make solid again. Or I might remove all of it and rebuild with wood and glass it. Without being there, it is hard to say exactly how I'd go about it, but to answer your question, yes, start over. Once you set your mind to it you will feel better and begin making progress.

I am not a fan of patching over damaged or weak areas. I approach things as I can do better than the original builder because look at how his work held up. Looking at your pictures I would tear out any damaged areas and get back to good solid glass and then build back. Once you make up your mind to get destructive the tear down will go faster than you think. It looks to me like you can cut the floor out, put some foam pink board down with all the hard edges rounded over, and glass over the top several times to rebuild a sturdy floor. For the coaming I would dig out all that flaky loose looking stuff and see if I could cut some wood pieces to epoxy back in, filling all voids, and make solid again. Or I might remove all of it and rebuild with wood and glass it. Without being there, it is hard to say exactly how I'd go about it, but to answer your question, yes, start over. Once you set your mind to it you will feel better and begin making progress.

Dylan

If you need some encouragement or ideas take a look at the boat repair made by @ChadW. He was dealing with similar issues and did a really nice job at resolving them. Better than new!

duckboats.net

duckboats.net

If you need some encouragement or ideas take a look at the boat repair made by @ChadW. He was dealing with similar issues and did a really nice job at resolving them. Better than new!

BBSB Rehab Help

Sorry for the confusion, I had a lot of problems posting. See below: looking to rehab the bottom of this old sneakbox. We've already started tearing the horizontal supports out, as they are broken and unrepairable. The previous repair attempts, by previous owners, have failed and we would like...

Dylan N

New member

Thanks Eric. Yeah it’s been a mental hurdle for me. Never done large glass work. But I’ve come to the mental conclusion I need to cut it out dry it out and start over. That foam looks like divinycell to me. I’ll begin work and post pics with updates. Idk what “foam pink board” is but I was gonna use divinycell.

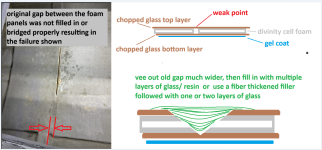

This would be my approach to the crack in the floor/hull.Thanks Eric. Yeah it’s been a mental hurdle for me. Never done large glass work. But I’ve come to the mental conclusion I need to cut it out dry it out and start over. That foam looks like divinycell to me. I’ll begin work and post pics with updates. Idk what “foam pink board” is but I was gonna use divinycell.

Attachments

Dylan N

New member

Eric I read that thread he has wood stringers and a totally different animal it seemsDylan

If you need some encouragement or ideas take a look at the boat repair made by @ChadW. He was dealing with similar issues and did a really nice job at resolving them. Better than new!

BBSB Rehab Help

Sorry for the confusion, I had a lot of problems posting. See below: looking to rehab the bottom of this old sneakbox. We've already started tearing the horizontal supports out, as they are broken and unrepairable. The previous repair attempts, by previous owners, have failed and we would like...duckboats.net

Dylan N

New member

Wow Dave that diagram is really good. Thank you for taking the time to do that. But that “crack” is what I grinder out where it was really flexing. It seems like the tin canning I’m getting is from the play between foam board and the hull.This would be my approach to the crack in the floor/hull.

He tore out all the bad, got to a strong base and then rebuilt from the ground up. Same approach I'd take with your situation.Eric I read that thread he has wood stringers and a totally different animal it seems