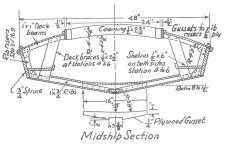

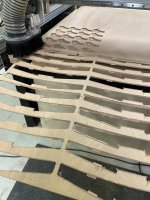

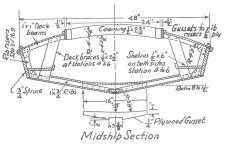

Once the side planks are installed it was time to make up the gussets for the rib assemblies. The plans call for a gusset on each side of the ribs notched to accept the keelson. I drafted the gusset in Fusion360 and cut the gussets on my CNC router. The gussets could easily be made on a table saw or with a jig saw. There are 10 ribs so I cut out 20 of the keelson gussets. The text and the plans are different. The plans state 1/4" gussets but the text says 3/8". I plan to fiberglass tape the side plank to bottom joint so I went with 1/4" oakume gussets.

There are small gussets that attach the ribs to rib risers. These gussets were drafted and routed. Again these could be made with a table saw or a jig saw. I opted to cut them out on my CNC router. There are 2 gussets per rib to rib riser joint so I cut out 20 gussets. I altered the gusset design and added a curve on the gusset inner side of the joint to maximize interior space.

The ribs are 1" deep by 3/4" wide and the rib risers are 1" by 1". The plans call for the rib risers to be a 3/4" to 1" rib riser. I built a tenoning jig for my table saw and cut a 1/4" half lap on the rib riser. I then trimmed the end of the rib riser to the side plank angle. This creates a half lap joint at the rib to rib riser joint.

The next step is to set the riser at station 6 and install the keelson.

Rick Lathrop

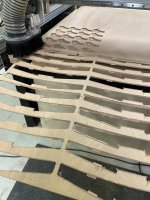

There are small gussets that attach the ribs to rib risers. These gussets were drafted and routed. Again these could be made with a table saw or a jig saw. I opted to cut them out on my CNC router. There are 2 gussets per rib to rib riser joint so I cut out 20 gussets. I altered the gusset design and added a curve on the gusset inner side of the joint to maximize interior space.

The ribs are 1" deep by 3/4" wide and the rib risers are 1" by 1". The plans call for the rib risers to be a 3/4" to 1" rib riser. I built a tenoning jig for my table saw and cut a 1/4" half lap on the rib riser. I then trimmed the end of the rib riser to the side plank angle. This creates a half lap joint at the rib to rib riser joint.

The next step is to set the riser at station 6 and install the keelson.

Rick Lathrop