J.P. Ward

Member

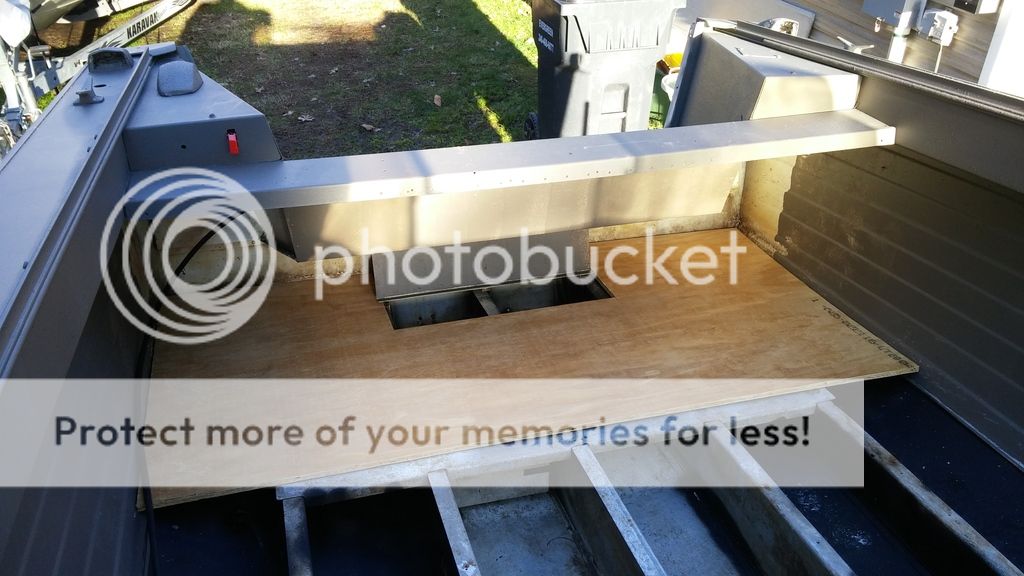

I've used both in boats that I've built or re-built. I don't like poured in as you can't inspect the areas under the foam once it is poured. I'm guessing your going to screw or glue some 3/4" ply over the top of the foam so your probably not going to be inspecting until that plywood goes bad.

In the case where I used blocks I purchased urethane flotation foam from a supplier and cut the blocks to shape. I'm not sure about the foams used for home insulation. It needs to be resistant to oil, gasoline, and whatever else may end up in the bilge. It needs to not absorb water over the life of the boat. I think you can probable buy the foam for less than you can buy the 2 part but I haven't bought any in a while. I think the blocks also allow some space to let water run through the bilges.

If your going to pour you just have too be careful to allow the foam room to expand. I don't think that will be an issue since you have the deck off.

Here is a link that has some good information.

[/url]https://www.glen-l.com/weblettr/webletters-7/wl55-flotation.html

In the case where I used blocks I purchased urethane flotation foam from a supplier and cut the blocks to shape. I'm not sure about the foams used for home insulation. It needs to be resistant to oil, gasoline, and whatever else may end up in the bilge. It needs to not absorb water over the life of the boat. I think you can probable buy the foam for less than you can buy the 2 part but I haven't bought any in a while. I think the blocks also allow some space to let water run through the bilges.

If your going to pour you just have too be careful to allow the foam room to expand. I don't think that will be an issue since you have the deck off.

Here is a link that has some good information.

[/url]https://www.glen-l.com/weblettr/webletters-7/wl55-flotation.html

Last edited: