Im going to try and ask the least questions possible watching this thread, but its bugging me. You made beautiful cuts, but noticed the cut of grain was different. Does grain cuts not matter because you will be glassing down the road? I know with decoy stuff, paying attention to grain direction is crucial for strong pieces. This is just curiosity since I am not a boat builder by any means.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2025 Devlin Snow Goose Thread

- Thread starter HenryHawthorne

- Start date

The advantage of plywood is that the plys alternate grain direction... so cutting them I'm only worried about maximizing pieces out of each panel. It will matter for the hardwoodIm going to try and ask the least questions possible watching this thread, but its bugging me. You made beautiful cuts, but noticed the cut of grain was different. Does grain cuts not matter because you will be glassing down the road? I know with decoy stuff, paying attention to grain direction is crucial for strong pieces. This is just curiosity since I am not a boat builder by any means.

Didnt realize this was plywood. Very good, sorry to distract... I digress.The advantage of plywood is that the plys alternate grain direction... so cutting them I'm only worried about maximizing pieces out of each panel. It will matter for the hardwood

A little progress - took the transom to my local dealer and used their template to mark the motor mount holes. Talking with the install tech, it does seem Tohatsu uses a standard mount, so as someone mentioned in the other thread, Tod, you may be able to use current holes when you get around to a new motor.

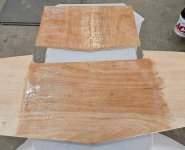

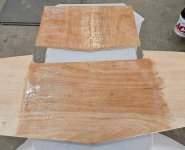

Also got the transom doubler cut and laminated. Good flow through the seep holes, so should be a good bonding. Will drill motor holes tomorrow.

Picked up a Seaview cable seal while there for the battery cables and fuel line as they come through the bulkhead into the motorwell. Nice product, will get a hole cut in the bulkhead for it tomorrow. Then think I can finally start mounting bulkheads to my strongback - hopefully Thursday.

Also got the transom doubler cut and laminated. Good flow through the seep holes, so should be a good bonding. Will drill motor holes tomorrow.

Picked up a Seaview cable seal while there for the battery cables and fuel line as they come through the bulkhead into the motorwell. Nice product, will get a hole cut in the bulkhead for it tomorrow. Then think I can finally start mounting bulkheads to my strongback - hopefully Thursday.

A little progress - took the transom to my local dealer and used their template to mark the motor mount holes. Talking with the install tech, it does seem Tohatsu uses a standard mount, so as someone mentioned in the other thread, Tod, you may be able to use current holes when you get around to a new motor.

Also got the transom doubler cut and laminated. Good flow through the seep holes, so should be a good bonding. Will drill motor holes tomorrow.

View attachment 64650

View attachment 64651

Picked up a Seaview cable seal while there for the battery cables and fuel line as they come through the bulkhead into the motorwell. Nice product, will get a hole cut in the bulkhead for it tomorrow. Then think I can finally start mounting bulkheads to my strongback - hopefully Thursday.

That looks great. I was wondering if there was a standard template for motors, that is good info, thanks!

Motor holes drilled oversized and filled with thickened epoxy. Think I'm going to change my plans a bit. As eager as I am to get the bulkheads mounted on my strongback and get building, I'm going to take a few days and epoxy coat them. Will be easier than dealing with runs once vertical.

Henry,

No idea if this is a good idea or bad but I've often wondered if it would be easier to seal the interior before stitching the hull and bulkheads together. Obviously you are forfeiting a chemical bond for a mechanical bond but it would be easier than when everything is assembled. What are your thoughts and those of you who are reading this post. Richard

No idea if this is a good idea or bad but I've often wondered if it would be easier to seal the interior before stitching the hull and bulkheads together. Obviously you are forfeiting a chemical bond for a mechanical bond but it would be easier than when everything is assembled. What are your thoughts and those of you who are reading this post. Richard

Funny, I've been contemplating that as I was putting epoxy on bulkheads today - and was going to ask the more experienced. The only downside I can think of would be any stiffness added to the panels and wonder whether that would be enough to make them harder to "shape" over the bulkheads. I'd still prime joints before glassing, so would have chemical bond there.Henry,

No idea if this is a good idea or bad but I've often wondered if it would be easier to seal the interior before stitching the hull and bulkheads together. Obviously you are forfeiting a chemical bond for a mechanical bond but it would be easier than when everything is assembled. What are your thoughts and those of you who are reading this post. Richard

Bulkheads epoxied and on the strongback.

Next is clean up of scarf joints then layout of the hull and side panels. Progress is slow, but sure.

I've also gotten my wiring, panel, lights, and battery panel and breakers ordered. Electrical stuff has also gotten expensive! But may as well do it right from the beginning.

Next is clean up of scarf joints then layout of the hull and side panels. Progress is slow, but sure.

I've also gotten my wiring, panel, lights, and battery panel and breakers ordered. Electrical stuff has also gotten expensive! But may as well do it right from the beginning.

Henry,

Just a suggestion, but you may want to run a temporary brace from starboard to port to each of your modified knees. I'm concerned they could fracture when the plywood is tortured into place.

Just a suggestion, but you may want to run a temporary brace from starboard to port to each of your modified knees. I'm concerned they could fracture when the plywood is tortured into place.

Thanks, would be easy to brace on the front side and use my electrical chase holes to bolt through (a block on the back side).Henry,

Just a suggestion, but you may want to run a temporary brace from starboard to port to each of your modified knees. I'm concerned they could fracture when the plywood is tortured into place.

I have everything aligned and screwed to the strongback posts - but will have to take a few down to modify post height so it doesn't extend beyond the bulkhead - but easy to do now that everything is aligned and I can just re-screw in the same spots. I haven't looked back to see if Devlin's plans specified higher mounting, but I'm not sure how much higher I could have gone. For those who do this upside down in the future, I will say the plans could be improved for #4 and #5 by moving the posts further out from the centerline - and would be required if going with the originally-designed knees. The plans put those posts where there is only air (I had to come up with some crossbracing across the top of them to give me something to attach to). I'll send a note and some pics to Sam, maybe he'll revise the plans.

Last edited:

Yes. In hindsight, I could have also left meat inside those "open bulkheads", but pretty sure I got the #1 bulkead and the nose doubler (or something else) out of the space in them.Henry,

I got around that issue by using a temporary bulkhead made of cheap OSB, then mounted my knees after flipping the hull right side up. Richard View attachment 64807

Yes. In hindsight, I could have also left meat inside those "open bulkheads", but pretty sure I got the #1 bulkead and the nose doubler (or something else) out of the space in them.

Beautiful work.

Love the laser level, they sure do come in handy (and that sure shows how nice your work is!). That is a tool I wish I had 30 years ago, I use my 3-plane all the time.

The building upside down is fascinating to me. I simply can't believe the process for a stitch and glue boat that way. I sure appreciate seeing it, but dang if that doesn't seem to go about as against the grain for stitch and glue as I can imagine.

Last edited:

Thanks - yes, it is quite useful for this. As I attached each new piece, there were still enough points visible through 2-3 bulkheads behind to ensure good alignment and lack of movement in between. A useful double-check!Beautiful work.

Love the laser level, they sure do come in handy (and that sure shows how nice your work is!). That is a tool I wish I had 30 years ago, I use my 3-plane all the time.

The building upside down is fascinating to me. I simply can't believe the process for a stitch and glue boat that way. I sure appreciate seeing it, but dang if that doesn't seem to go about as against the grain for stitch and glue as I can imagine.

As for upside down, I really went back and forth in my mind. Ultimately, I decided I had taken so much of your advice and guidance that if I wanted respect from the other members of this forum I had better go against you at least once.

Thanks - yes, it is quite useful for this. As I attached each new piece, there were still enough points visible through 2-3 bulkheads behind to ensure good alignment and lack of movement in between. A useful double-check!

As for upside down, I really went back and forth in my mind. Ultimately, I decided I had taken so much of your advice and guidance that if I wanted respect from the other members of this forum I had better go against you at least once.

So, how much do you accomplish before you flip? All I'm seeing are limitations, but I haven't read anything or thought about it.

One of the big selling points of stitch and glue was not building an extensive form, it seems like that strongback is a pretty serious construction. I 100% accept that I'm probably missing something.

Last edited:

I think the primary advantage is limiting flips. I'll get at least to paint prep before flipping - and likely get the bottom painted before flipping. The other advantage is not having to individually fit the bulkheads, as the hull is formed around and to them rather than the other way around. At least those are the reasons Devlin states for moving to this method on all but the smallest of boats. We'll see.So, how much do you accomplish before you flip? All I'm seeing are limitations, but I haven't read anything or thought about it.

One of the big selling points of stitch and glue was not building an extensive form, it seems like that strongback is a pretty serious construction. I 100% accept that I'm probably missing something.

This.... This is when he knew he F***** up!As for upside down, I really went back and forth in my mind. Ultimately, I decided I had taken so much of your advice and guidance that if I wanted respect from the other members of this forum I had better go against you at least once.

JK awesome work sir. This is coming along for you. Fun to sit back and watch.

I think the primary advantage is limiting flips. I'll get at least to paint prep before flipping - and likely get the bottom painted before flipping. The other advantage is not having to individually fit the bulkheads, as the hull is formed around and to them rather than the other way around. At least those are the reasons Devlin states for moving to this method on all but the smallest of boats. We'll see.

Are you glassing the interior fillets upside down? That is the thing I'm having the hardest time with.

I'm undecided on that one. I suspect I will up near the bowl where the bend and pressure are the greatest, but I'm going to decide when I get there. Initially I'm going to epoxy between stitches from the exterior - then pop under and decide how much to do. I'll fully fillet and glass the vertical bulkeads to side panels joints from underneath, so I'm suspecting that and the epoxy between stitches from outside will be plenty to keep things in shape as stitches are removed. But, TBD.Are you glassing the interior fillets upside down? That is the thing I'm having the hardest time with.