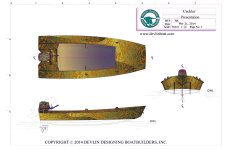

G’day, I’m Matthias, live in Sydney Australia and I’m building the Devlin designed Cackler 14.

Backstory

Why am I building a duck boat? Briefly: used to live in Mildura, which is roughly halfway down the Murray River, Australia’s longest river and wanted a custom camping and river exploring boat. Devlin’s Honker 18 seemed like the ticket so I bought the plans and got ready to build. Life changed, moved to Sydney, build plans and desire ceased. Fast forward to January 2025 when with a group of mates I signed up for an event called The Tinny Rally. I don’t own a boat so instead of buying one thought it would be cool to build one instead and revive the Honker build dream. But Honker’s size is a tad large for the Rally, so decided to build its smaller sibling instead.

I’m building the boat at work (small signage and display business) which is good because there are heaps of tools, but also bad because our factory is tiny and there is no dedicated space available to build, so sometimes the boat hangs from the ceiling, sometimes it’s on trestles and sometimes it’s just lying on the ground.

I did contemplate buying a CNC cut aluminium boat kit and welding that, but even though I’m not a woodworker a plywood build seemed easier and more fun. So here we are…

The pic below is the current build state, but I’ll post retrospective pics so you can see how I got to this point.

Backstory

Why am I building a duck boat? Briefly: used to live in Mildura, which is roughly halfway down the Murray River, Australia’s longest river and wanted a custom camping and river exploring boat. Devlin’s Honker 18 seemed like the ticket so I bought the plans and got ready to build. Life changed, moved to Sydney, build plans and desire ceased. Fast forward to January 2025 when with a group of mates I signed up for an event called The Tinny Rally. I don’t own a boat so instead of buying one thought it would be cool to build one instead and revive the Honker build dream. But Honker’s size is a tad large for the Rally, so decided to build its smaller sibling instead.

I’m building the boat at work (small signage and display business) which is good because there are heaps of tools, but also bad because our factory is tiny and there is no dedicated space available to build, so sometimes the boat hangs from the ceiling, sometimes it’s on trestles and sometimes it’s just lying on the ground.

I did contemplate buying a CNC cut aluminium boat kit and welding that, but even though I’m not a woodworker a plywood build seemed easier and more fun. So here we are…

The pic below is the current build state, but I’ll post retrospective pics so you can see how I got to this point.

Attachments

Last edited: