You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question For Dave McCann and Any Other Machinist

- Thread starter Eric Patterson

- Start date

You sound just like a desk jockey in the tool and die shop.I have no idea what yall are talking about but it’s pretty cool looking

Eric,Dave

That helps out a lot. With this set up how would I adjust the final height of the cutter, hence the diameter(s) of the turned part? Make "A" slightly shorter to begin with and then shim under it to final diameter? It looks like you have drawn it with a bit of room available to shim. Also, is part B cantilevered over part A or are they the same length front to back? Thanks.

Dovetail form and skive tools are available, again mostly confined to the screw machine industry. The holders operate similar to an Aloris style tool post but orientated horizontally. As far as height adjustment, if tolerance is wide open, and repeatability from setup to setup is not relevant then you may not miss it. But many factors such as machine rigidity, or lack of, material hardness, deflection caused by tool pressure and or machine wear can all add up to give the perfectionist fits.

Most flat form and skive tools are produced using an EDM, it's very cost effective vs milling or grinding.

Attachments

BrianEric,

Dovetail form and skive tools are available, again mostly confined to the screw machine industry. The holders operate similar to an Aloris style tool post but orientated horizontally. As far as height adjustment, if tolerance is wide open, and repeatability from setup to setup is not relevant then you may not miss it. But many factors such as machine rigidity, or lack of, material hardness, deflection caused by tool pressure and or machine wear can all add up to give the perfectionist fits.

Most flat form and skive tools are produced using an EDM, it's very cost effective vs milling or grinding.

How wide are the cutters pictured? I can't figure out if that thing can hold the cutter I intend to use. I wish I could understand their literature. I'm not getting it.

Eric,Brian

How wide are the cutters pictured? I can't figure out if that thing can hold the cutter I intend to use. I wish I could understand their literature. I'm not getting it.

The dovetail blanks would be burned to your drawing of the required profile. The actual dovetail (clamping componant) size would be dictated by your cross slide width and t-nut size (base has to fit onto). In your application I believe your 3.0 + or - would be no problem, considering your cutting wood.

I did not realize you had the cutter already, my bad. My suggestion involves the holder and the cutter, with matching standard dovetails on each.

Brian

I don't have the cutter. I've contacted several tooling companies and am waiting to hear back . I will check this week but believe the cross slide width is right at 3 1/2". I've ordered t-nuts and they will be here any day now. The skiving dovetail holder sort of looks like it will hang was over the front edge of the cross slide. That kind of worries me letting it have that much leverage. Maybe the forces are light in that direction.

I don't have the cutter. I've contacted several tooling companies and am waiting to hear back . I will check this week but believe the cross slide width is right at 3 1/2". I've ordered t-nuts and they will be here any day now. The skiving dovetail holder sort of looks like it will hang was over the front edge of the cross slide. That kind of worries me letting it have that much leverage. Maybe the forces are light in that direction.

Chuck center line to top of cross slide?Brian

I don't have the cutter. I've contacted several tooling companies and am waiting to hear back . I will check this week but believe the cross slide width is right at 3 1/2". I've ordered t-nuts and they will be here any day now. The skiving dovetail holder sort of looks like it will hang was over the front edge of the cross slide. That kind of worries me letting it have that much leverage. Maybe the forces are light in that direction.

If standard flat skive tooling is quoted then by all means Dave's sketch would suit you well. Flat tooling does offer less involved regrinding, though wood and low production probably indicates sharpened for life

Another thought, if your cross slide is that wide you can search the machine shop auctions for #2 B&S screw machine tooling, typically a penny a pound. You may locate something that either fits or fits with slight mods.

Richard Lathrop

Well-known member

This is a production design question. What is best machine for cost to produce the item. I was guessing you wanted to turn duck calls. What is advantage of using milled knife versus the shaped knife?Richard

I'm sure that is so in a lot of cases, but I've never heard of CNC being used to T&G flooring. I'll try and get some pictures of some cutterheads I have that are mill-to-pattern and I think you'll see CNC would not be practical. But for the problem I'm working on now you are probably correct. Also back knife and rotary lathes could very well do what I'm trying to do but I don't want to buy another machine. If I can get a cutter made at a reasonable price I'll be able to make more than the occasional duck call on equipment I already have.

Rick

Richard

If we are talking about the same thing a flat knife ground to profile scrapes. I've never had luck scraping profiles more than about 1/2" wide. Too much chatter, burning and tearout. I want a shearing cut for an acceptable finish. Flat knives ground to profile are used in rotary lathes (cutter head spins while stock slowly turns) but I'm not interested in buying one.

If we are talking about the same thing a flat knife ground to profile scrapes. I've never had luck scraping profiles more than about 1/2" wide. Too much chatter, burning and tearout. I want a shearing cut for an acceptable finish. Flat knives ground to profile are used in rotary lathes (cutter head spins while stock slowly turns) but I'm not interested in buying one.

Last edited:

Brian

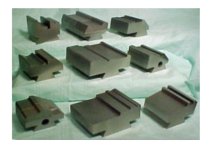

Up above you show a picture of dovetail knives. Who is the supplier of those? I want to look into that option but need more info. Thank you!

Up above you show a picture of dovetail knives. Who is the supplier of those? I want to look into that option but need more info. Thank you!

I resemble that remarkYou sound just like a desk jockey in the tool and die shop.

Brian

Up above you show a picture of dovetail knives. Who is the supplier of those? I want to look into that option but need more info. Thank you!

Specialty Tooling – Lester Detterbeck Enterprises Ltd.

www.lesterdetterbeck.com

www.lesterdetterbeck.com

Richard Lathrop

Well-known member

Thanks, I was reading the Delta document and looking at the other options. I was reading the list of manufacturing options based on unit counts across the bottom of the prior page. Looking forward to seeing your solution.Richard

If we are talking about the same thing a flat knife ground to profile scrapes. I've never had luck scraping profiles more than about 1/2" wide. Too much chatter, burning and tearout. I want a shearing cut for an acceptable finish. Flat knives ground to profile are used in rotary lathes (cutter head spins while stock slowly turns) but I'm not interested in buying one.

Rick

Richard

I think my copy is missing that page. I'll check tonight.

I think my copy is missing that page. I'll check tonight.

Richard Lathrop

Well-known member

Pages 10 and 11Richard

I think my copy is missing that page. I'll check tonight.

Update:

I got a quote from Slater tools on that skiving dovetail tool holder. I studied it more last night and think it might work. Quote came back $1529. Not in the budget. I'm going to look on ebay tonight but seriously doubt I'll find one. Maybe a substitute is out there. I'm still waiting on a quote for three HSS dovetail blanks from Somma Tool Co. My searches for skiving stuff started turning up companies that will make custom cutters from dovetail blanks. This leads me to believe one of them might be able to make a custom cutter for me at a reasonable price since they routinely make them.

Also, I heard back from a lathe tooling company I reached out to. I sent him the picture at the top of this thread. He likened the set-up to that of a back knife lathe (I agree with the comparison) and said if I can send him a sample he'd see if they can make a knife for it. In that case I may be back to a tool holder something like Dave drew.

Thanks to all that have contributed, especially Dave and Brian. I'm out of my element but simple things like learning the terms "shiving", "screw machine", and "dovetail tool holder" help me search out solutions.

I got a quote from Slater tools on that skiving dovetail tool holder. I studied it more last night and think it might work. Quote came back $1529. Not in the budget. I'm going to look on ebay tonight but seriously doubt I'll find one. Maybe a substitute is out there. I'm still waiting on a quote for three HSS dovetail blanks from Somma Tool Co. My searches for skiving stuff started turning up companies that will make custom cutters from dovetail blanks. This leads me to believe one of them might be able to make a custom cutter for me at a reasonable price since they routinely make them.

Also, I heard back from a lathe tooling company I reached out to. I sent him the picture at the top of this thread. He likened the set-up to that of a back knife lathe (I agree with the comparison) and said if I can send him a sample he'd see if they can make a knife for it. In that case I may be back to a tool holder something like Dave drew.

Thanks to all that have contributed, especially Dave and Brian. I'm out of my element but simple things like learning the terms "shiving", "screw machine", and "dovetail tool holder" help me search out solutions.

Last edited:

Try Magnaport International. RMI'm still trying to find a shop that can do the EDM work needed to make the cutter. I say EDM because I understand that is the method used these days to make such cuts in thick steel.

RM

I googled them and came up with a company that ports shotguns. I'm not sure how they can help in this instance.

I googled them and came up with a company that ports shotguns. I'm not sure how they can help in this instance.

Eric,RM

I googled them and came up with a company that ports shotguns. I'm not sure how they can help in this instance.

They also port rifles and handguns using electrical discharge machining or EDM. If they are hungry for work, perhaps they can help you. My thinking was perhaps a gunsmith would be more agreeable to doing a one of. The hardest part is getting past their receptionist. RM

Last edited: